IE5 380V TYZD High Power Direct-drive Loads Low-speed Permanent Magnet Synchronous Motor

Product specification

| Rated voltage | 380V,415V,460V... |

| Power range | 30-500kW |

| Speed | 0-300rpm |

| Frequency | Variable frequency |

| Phase | 3 |

| Poles | By technical design |

| Frame range | 355-800 |

| Mounting | B3,B35,V1,V3..... |

| Isolation grade | H |

| Protection grade | IP55 |

| Working duty | S1 |

| Customized | Yes |

| Production cycle | 30days |

| Origin | China |

Product features

• High efficiency and power factor.

• Permanent magnets excitation, do not need excitation current.

• Synchronous operation, there is no speed pulsation.

• Can be designed into high starting torque and overload capacity.

• Low noise, temperature rise and vibration.

• Reliable operation.

• With a frequency inverter for variable speed applications.

Product Applications

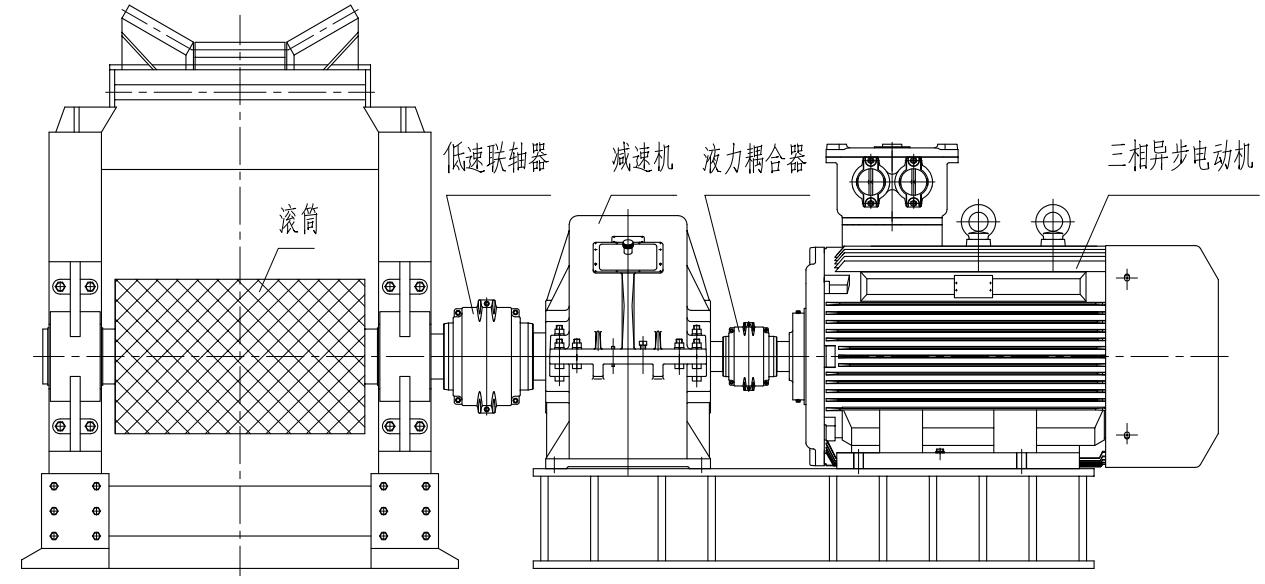

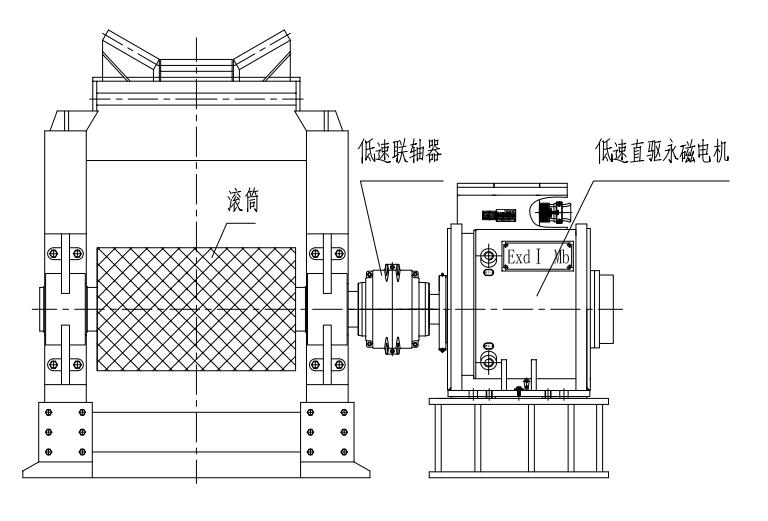

The series products are widely used in various equipments such as ball mills, belt machines, mixers, direct drive oil pumping machines, plunger pumps, cooling tower fans, hoists, etc. in coal mines, mines, metallurgy, electric power, chemical industry, building materials and other industrial and mining enterprises.

FAQ

What are the motor mounting types?

The structure and mounting type designation of the motor is consistent with IEC60034-7-2020.

That is, it consists of the capital letter "B" for "IM" for "horizontal installation" or the capital letter "v" for "vertical installation" together with one or two Arabic numerals, e.g.: "IM" for "horizontal installation" or "B" for "vertical installation". "v" with 1 or 2 Arabic numerals, e.g..

"IMB3" denotes two end-cap, footed, shaft-extended, horizontal installations mounted on foundation members.

"IMB35" denotes a horizontal mounting with two end caps, feet, shaft extensions, flanges on the end caps, through holes in the flanges, flanges mounted on the shaft extensions, and feet mounted on the base member with the flanges attached.

"IMB5" means two end caps, no foot, with shaft extension, end caps with flange, flange with through hole, flange mounted on the shaft extension, mounted on the base member or ancillary equipment with flange "IMV1" means two end caps, no foot, shaft extension to the bottom, end caps with flange, flange with through hole, flange mounted on the shaft extension, mounted on the bottom with flange vertical mounting. "IMV1" stands for vertical mounting with two end caps, no foot, shaft extension downwards, end caps with flanges, flanges with through holes, flanges mounted on the shaft extension, mounted on the bottom by means of flanges.

Some of the most commonly used mounting options for low voltage motors are: IMB3, IMB35, IMB5, IMV1, etc.

Which method is effective in avoiding galvanic corrosion of bearings?

Insulate the shaft, Using insulated bearings, Insulate the end cover and adding carbon brushes.