IE5 10000V TYZD Low-speed Direct-drive Loads Permanent Magnet Synchronous Motor

Product specification

| Rated voltage | 10000V |

| Power range | 200-1400kW |

| Speed | 0-300rpm |

| Frequency | Variable frequency |

| Phase | 3 |

| Poles | By technical design |

| Frame range | 630-1000 |

| Mounting | B3,B35,V1,V3..... |

| Isolation grade | H |

| Protection grade | IP55 |

| Working duty | S1 |

| Customized | Yes |

| Production cycle | 30days |

| Origin | China |

Product features

• High efficiency and power factor.

• Permanent magnets excitation, do not need excitation current.

• Synchronous operation, there is no speed pulsation.

• Can be designed into high starting torque and overload capacity.

• Low noise, temperature rise and vibration.

• Reliable operation.

• With a frequency inverter for variable speed applications.

Product Applications

The series products are widely used in various equipments such as ball mills, belt machines, mixers, direct drive oil pumping machines, plunger pumps, cooling tower fans, hoists, etc. in coal mines, mines, metallurgy, electric power, chemical industry, building materials and other industrial and mining enterprises.

FAQ

How are bearings replaced?

All permanent magnet synchronous direct-drive motors have a special support structure for the rotor part, and the replacement of bearings on site is the same as that of asynchronous motors. Later bearing replacement and maintenance can save logistics costs, save maintenance time, and better protect the user's production reliability.

What are the key points of direct drive motor selection?

1. On-site operating mode:

Such as load type, environmental conditions, cooling conditions, etc.

2. Original transmission mechanism composition and parameters:

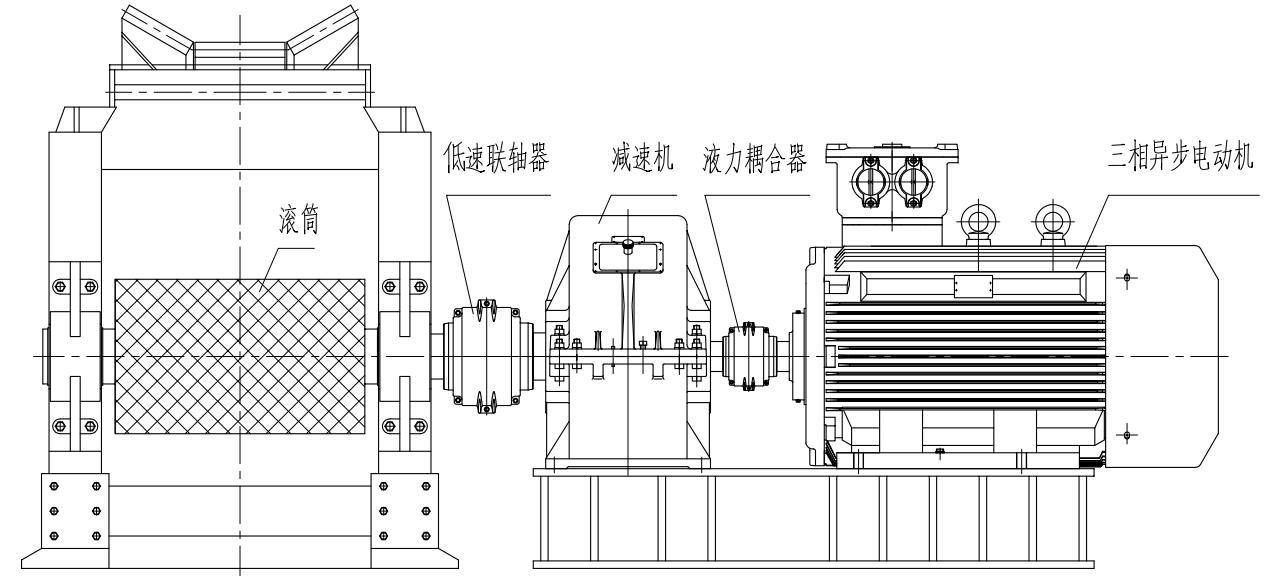

Such as the nameplate parameters of the reducer, interface size, sprocket parameters, such as tooth ratio and shaft hole.

3. Intent to remodel:

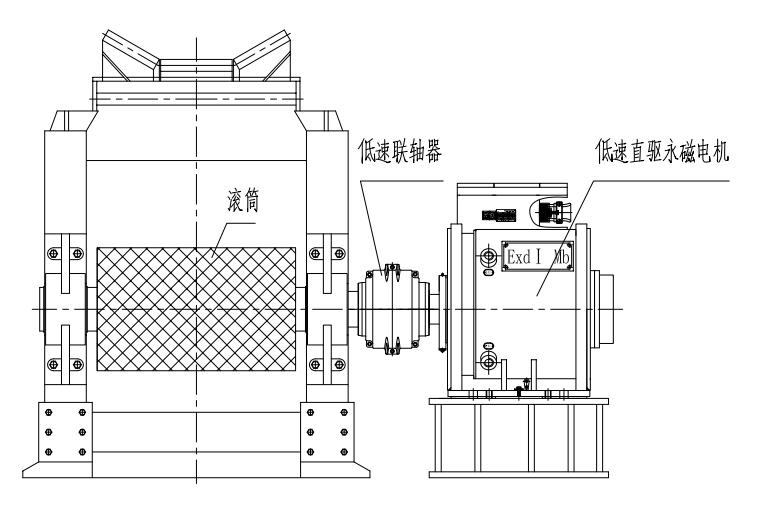

Specifically whether to do direct drive or semi-direct drive, because the motor speed is too low, you must do closed-loop control, and some inverters do not support closed-loop control. In addition the motor efficiency is lower, while the motor cost is higher, the cost-effective is not high. The enhancement is the advantage of reliability and maintenance-free.

If cost and cost-effectiveness are more important, there are some conditions where a semi-direct-drive solution may be appropriate while ensuring reduced maintenance.

4. Controlling demand:

Whether the inverter brand is mandatory, whether the closed loop is required, whether the motor to the inverter communication distance should be equipped with an electronic control cabinet, what functions should the electronic control cabinet have, and what communication signals are required for remote DCS.