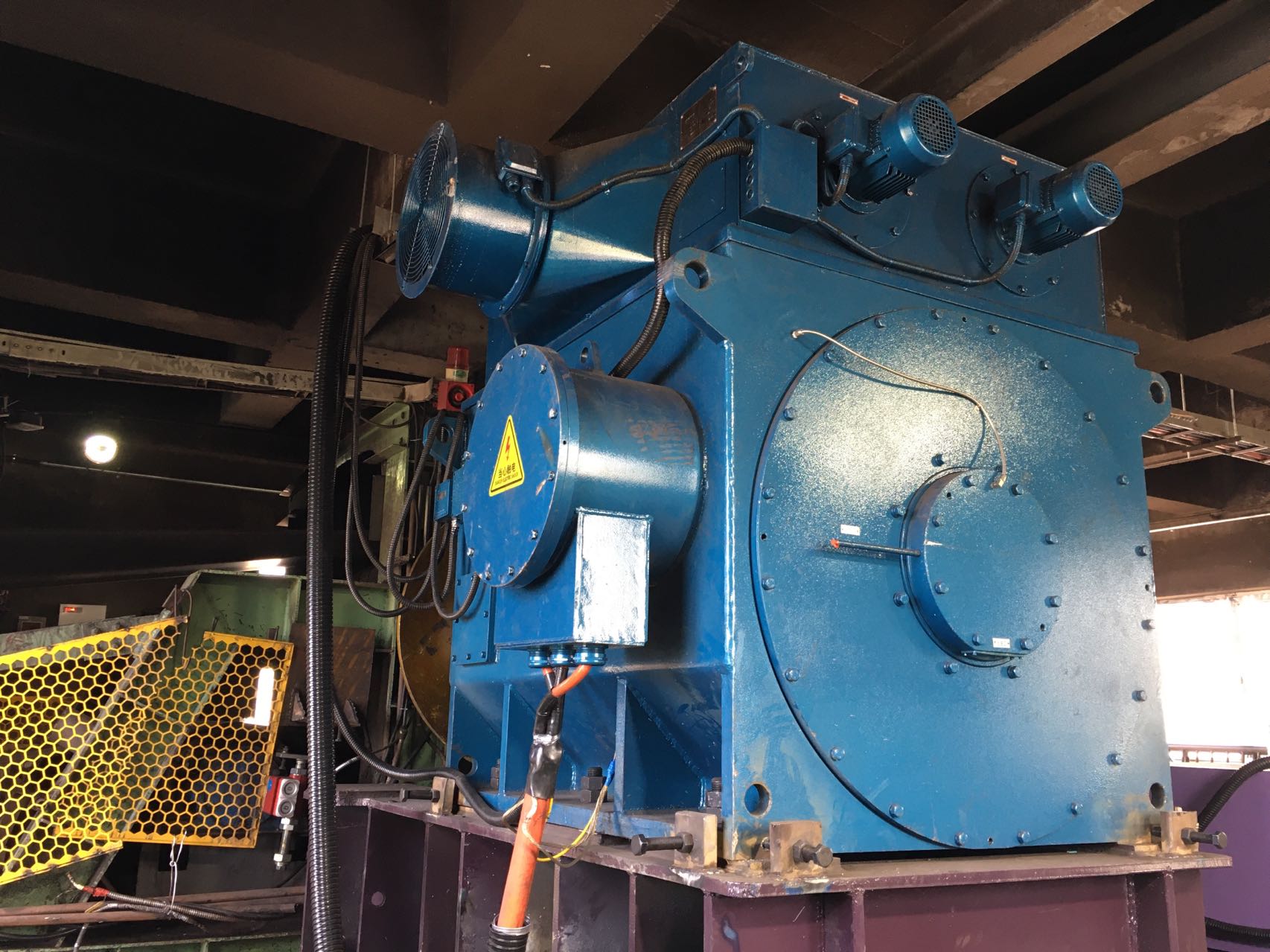

IE5 6000V TYZD Low-speed Direct-drive Loads Permanent Magnet Synchronous Motor

Product specification

| Rated voltage | 6000V |

| Power range | 200-1400kW |

| Speed | 0-300rpm |

| Frequency | Variable frequency |

| Phase | 3 |

| Poles | By technical design |

| Frame range | 630-1000 |

| Mounting | B3,B35,V1,V3..... |

| Isolation grade | H |

| Protection grade | IP55 |

| Working duty | S1 |

| Customized | Yes |

| Production cycle | 30days |

| Origin | China |

Product features

• High efficiency and power factor.

• Permanent magnets excitation, do not need excitation current.

• Synchronous operation, there is no speed pulsation.

• Can be designed into high starting torque and overload capacity.

• Low noise, temperature rise and vibration.

• Reliable operation.

• With a frequency inverter for variable speed applications.

Product Applications

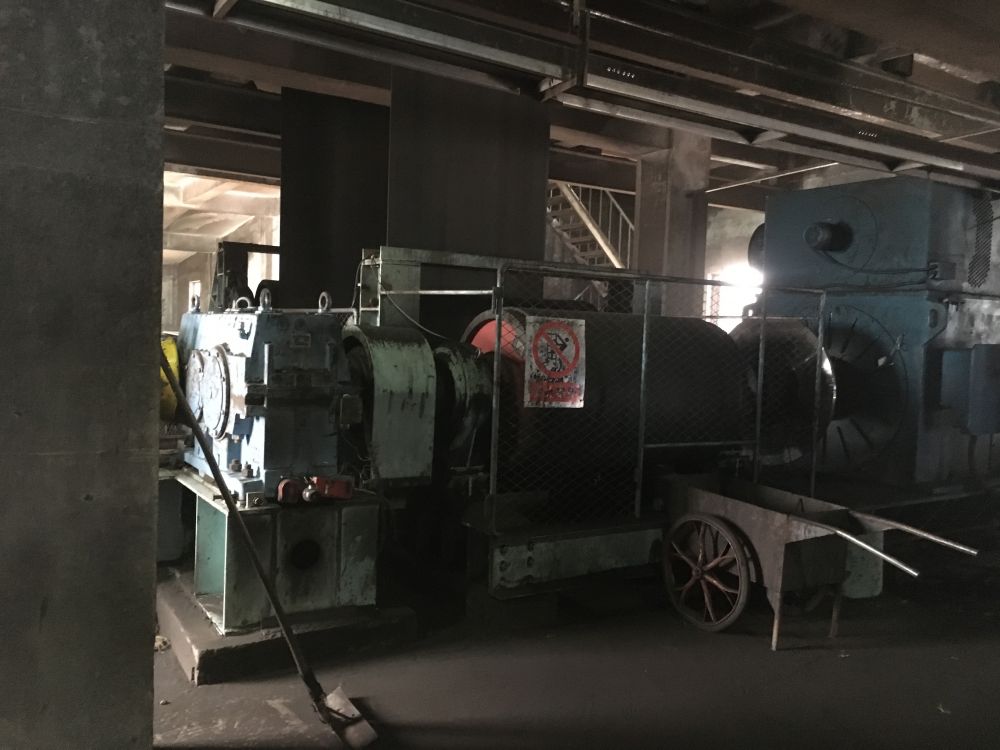

The series products are widely used in various equipments such as ball mills, belt machines, mixers, direct drive oil pumping machines, plunger pumps, cooling tower fans, hoists, etc. in coal mines, mines, metallurgy, electric power, chemical industry, building materials and other industrial and mining enterprises.

FAQ

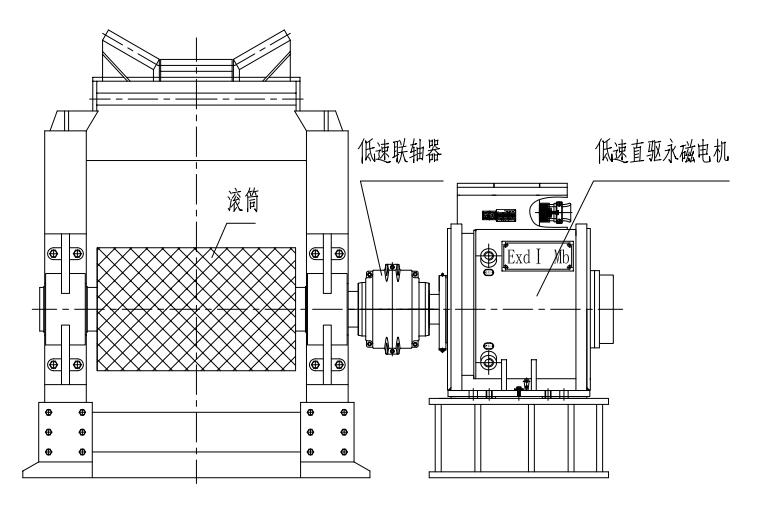

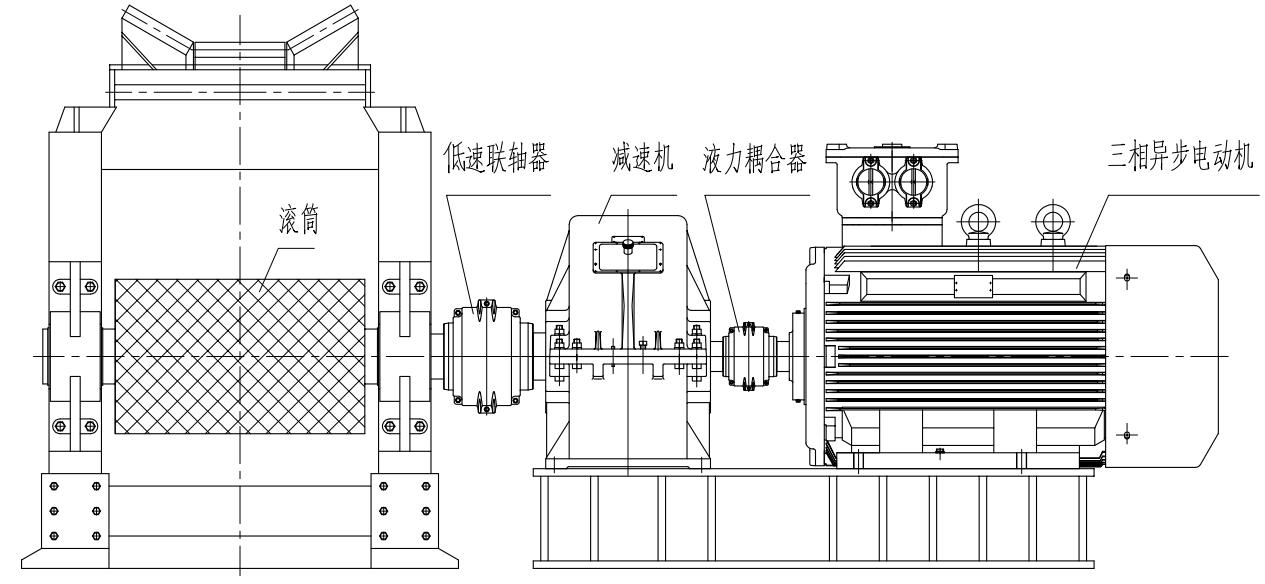

Background on low-speed direct-drive permanent magnet motors?

Relying on the update of inverter technology and the development of permanent magnet materials, it provides the basis for the realization of low-speed direct-drive permanent magnet motors.

In industrial and agricultural production and automatic control, often need to use low-speed drive, before the general use of electric motors plus reducers and other deceleration devices to realize. Although this system can achieve the purpose of low-speed. But there are also many shortcomings, such as complex structure, large size, noise and low efficiency.

Principle of permanent magnet synchronous motor and starting method?

As the stator rotating magnetic field speed is synchronous speed, while the rotor is at rest at the instant of starting, there is relative motion between the air gap magnetic field and the rotor poles, and the air gap magnetic field is changing, which cannot produce an average synchronous electromagnetic torque, i.e., there is no starting torque in the synchronous motor itself, so that the motor starts on its own.

In order to solve the starting problem, other methods must be taken, commonly used:

1, frequency conversion starting method: the use of frequency conversion power supply to make the frequency slowly rise from zero, the rotating magnetic field traction rotor slowly synchronous acceleration until it reaches the rated speed, starting is complete.

2, asynchronous starting method: in the rotor with a starting winding, its structure is like the asynchronous machine squirrel cage winding. Synchronous motor stator winding connected to the power supply, through the role of the starting winding, generating starting torque, so that the synchronous motor to start by itself, when the speed up to 95% of the synchronous speed or so, the rotor is automatically drawn into synchronization.