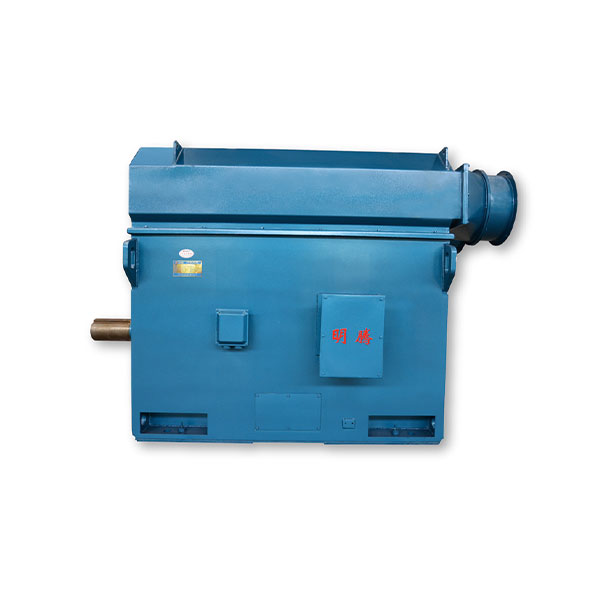

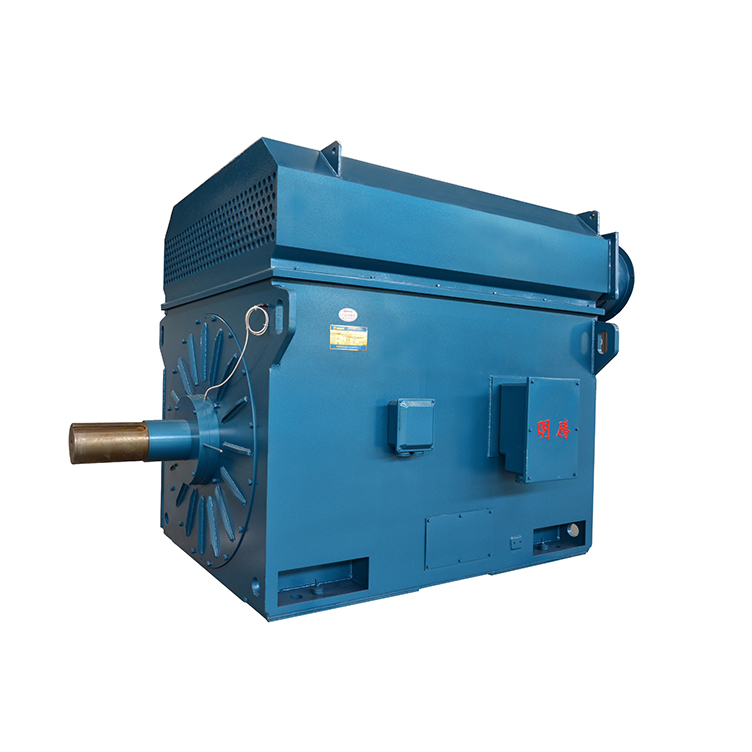

IE5 6000V TYPKK Variable Frequency permanent magnet synchronous motor

Product description

| Rated voltage | 6000V |

| Power range | 185-5000kW |

| Speed | 500-1500rpm |

| Frequency | Variable frequency |

| Phase | 3 |

| Poles | 4,6,8,10,12 |

| Frame range | 450-1000 |

| Mounting | B3,B35,V1,V3..... |

| Isolation grade | H |

| Protection grade | IP55 |

| Working duty | S1 |

| Customized | Yes |

| Production cycle | Standard 45days, Customized 60days |

| Origin | China |

Product features

• High efficiency and power factor.

• Permanent magnets excitation, do not need excitation current.

• Synchronous operation, there is no speed pulsation.

• Can be designed into high starting torque and overload capacity.

• Low noise, temperature rise and vibration.

• Reliable operation.

• With a frequency inverter for variable speed applications.

Product Applications

The series products are widely used in various equipments such as fans, pumps, compressors belt machines refining machines in electric power, water conservancy, petroleum, chemical industry, building materials, metallurgy, mining and other fields.

FAQ

Technical characteristics of permanent magnet motors?

1.Rated power factor 0.96~1;

2.1.5%~10% increase in rated efficiency;

3.Energy saving of 4%~15% for high voltage series ;

4.Energy saving of 5%~30% for low voltage series;

5.Reduction of operating current by 10% to 15%;

6.Speed synchronization with excellent control performance;

7.Temperature rise reduced by more than 20K.

Common Faults of Frequency Converter?

1. During V/F control, the frequency converter reports a filtering fault and increases the lifting torque by setting it to increase the motor output torque and reduce the current during the startup process;

2. When V/F control is applied, when the current value of the motor is too high at the rated frequency point and the energy-saving effect is poor, the rated voltage value can be adjusted to reduce the current:

3. During vector control, there is a self-tuning error, and it is necessary to verify whether the nameplate parameters are correct. Simply calculate whether the relevant relationship is correct by n=60fp, i=P/1.732U

4. High frequency noise: noise can be reduced by increasing the carrier frequency, which can be selected according to the recommended values in the manual;

5. When starting, the motor output shaft cannot operate normally: it needs to be repeated self-learning or changed self-learning mode;

6. When starting, if the output shaft can operate normally and an overcurrent fault is reported, the acceleration time can be adjusted;

7. During operation, overcurrent fault is reported: When the motor and frequency converter models are selected correctly, the general situation is motor overload or motor failure.

8. Overvoltage fault: When selecting deceleration shutdown, if the deceleration time is too short, it can be handled by extending the deceleration time, increasing the braking resistance, or changing to free parking

9. Short circuit to ground fault: Possible motor insulation aging, poor wiring on the motor load side, motor insulation should be checked and wiring should be checked for grounding;

10. Ground fault: The frequency converter is not grounded or the motor is not grounded. Check the grounding condition, if there is interference around the frequency converter, such as the use of walkie talkies.

11. During closed-loop control, faults are reported: incorrect nameplate parameter settings, low coaxiality of encoder installation, incorrect voltage given by encoder, interference from encoder feedback cable, etc.