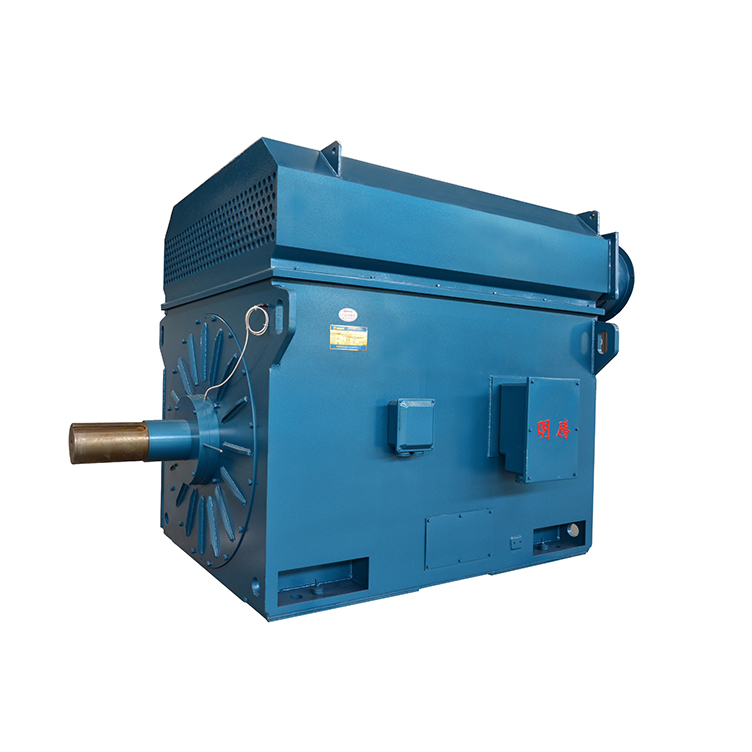

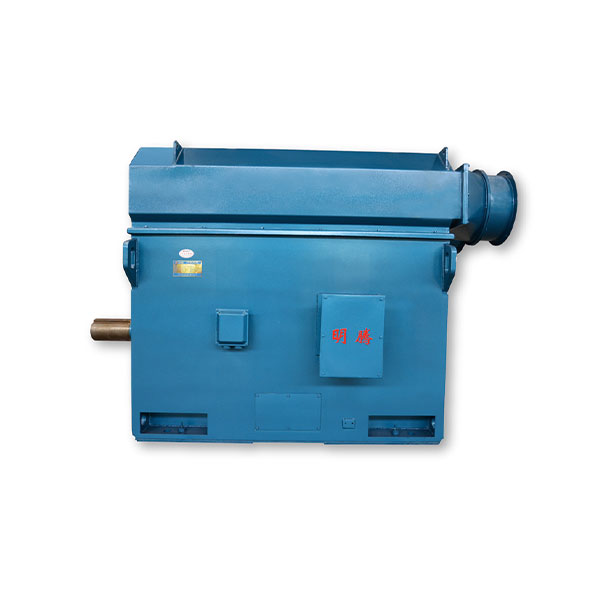

IE5 10000V TYKK Direct-Starting Permanent Magnet Synchronous Motor

Product specification

| Rated voltage | 10000V |

| Power range | 220-5000kW |

| Speed | 500-1500rpm |

| Frequency | Industrial frequency |

| Phase | 3 |

| Poles | 4,6,8,10,12 |

| Frame range | 450-1000 |

| Mounting | B3,B35,V1,V3..... |

| Isolation grade | H |

| Protection grade | IP55 |

| Working duty | S1 |

| Customized | Yes |

| Production cycle | 30days |

| Origin | China |

Product features

• High efficiency and power factor.

• Permanent magnets excitation, do not need excitation current.

• Synchronous operation, there is no speed pulsation.

• Can be designed into high starting torque and overload capacity.

• Low noise, temperature rise and vibration.

• Reliable operation.

• With a frequency inverter for variable speed applications.

FAQ

What is the permanent magnet synchronous motors working principle?

In short, the working principle of permanent magnet synchronous motor is: the inverter outputs rotating current to form a rotating magnetic field in the stator, which attracts the rotor (embedded with permanent magnets) to rotate in the same direction and at the same speed, generating constant directional torque, thus doing work or generating electricity externally. When the stator magnetic field exceeds the rotor magnetic field, it is the stator that attracts the rotor to run and do work externally, and when the stator magnetic field lags behind the rotor sub-magnetic field, it is the stator that attracts the rotor in the direction opposite to the rotational speed and prevents it from running, thus realizing power generation.

What are the advantages of PMSM?

1.High power factor, high grid quality factor, no need to add power factor compensator;

2.High efficient with low energy consumption and high power saving benefits;

3.Low motor current, saving transmission and distribution capacity and reducing overall system costs.

4.The motors can be designed for direct starting and can fully replace asynchronous motors.

5.Adding the driver can realize soft start, soft stop, and infinitely variable speed regulation, and the power saving effect is further improved;

6.The design can be targeted according to the requirements of the load characteristics, and can directly face the end-load demand;

7.The motors are available in a multitude of topologies and directly meet the fundamental requirements of the mechanical equipment in a wide range and under extreme conditions; the

8.The aim is to increase system efficiency, shorten the drive chain and reduce maintenance costs;

9.We can design and manufacture low speed direct drive permanent magnet motors to meet the higher requirements of users.