IE5 380V TYCX Direct-Starting Permanent Magnet Synchronous Motor

Product specification

| Rated voltage | 380V,415V,460V... |

| Power range | 5.5-315kW |

| Speed | 500-3000rpm |

| Rated frequency | Industrial frequency |

| Phase | 3 |

| Poles | 2,4,6,8,10,12 |

| Frame range | 90-355 |

| Mounting | B3,B35,V1,V3..... |

| Isolation grade | H |

| Protection grade | IP55 |

| Working duty | S1 |

| Customized | Yes |

| Production cycle | 30days |

| Origin | China |

Product features

• High efficiency(IE5) and power factor(≥0.96).

• Permanent magnets excitation, do not need excitation current.

• Synchronous operation, there is no speed pulsation.

• Permanent magnet synchronous motor can be designed into high starting torque and overload capacity.

• Permanent magnet electric motor is low noise, temperature rise and vibration.

• Reliable operation.

• With a variable speed drive (VSD) for variable speed applications.

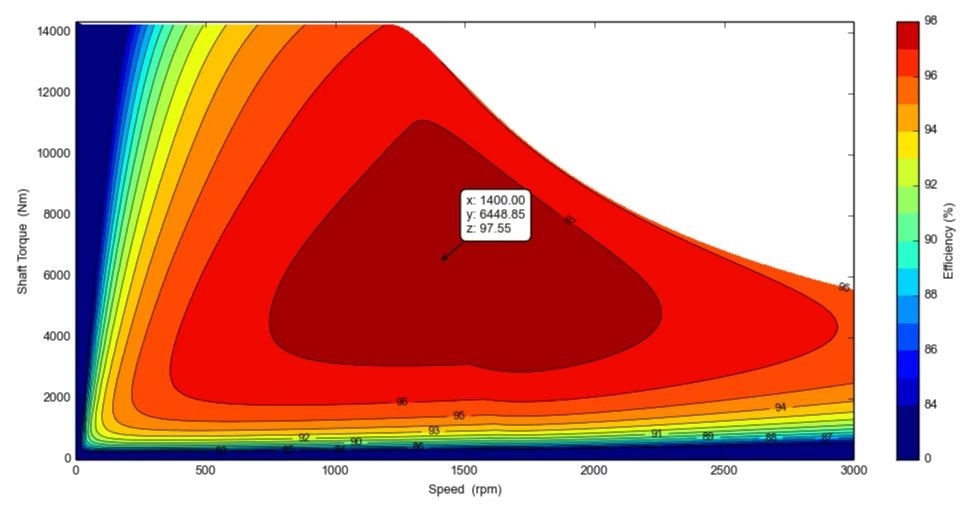

Permanent magnet motor efficiency map

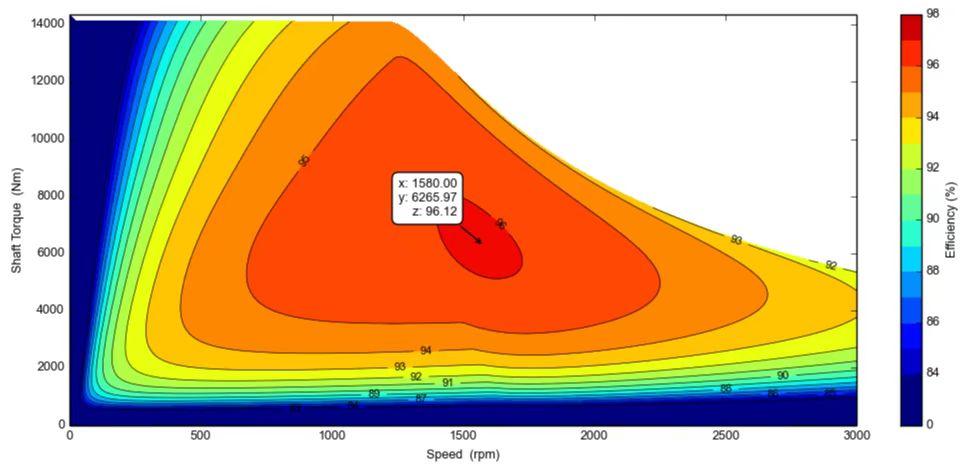

Asynchronous motor efficiency map

FAQ

What are the motor nameplate data?

The nameplate of the motor is labeled with important parameters of the motor, including at least the following information: name of manufacturer, motor name, model, protection class, rated power, rated frequency, rated current, rated voltage, rated speed, thermal classification, wiring method, efficiency, power factor, factory number and standard number, etc.

What are the advantages of Mingteng PM motors over other brands of PM motors?

1.The level of design is not the same

We have a professional R & D team of more than 40 people, after 16 years of technical experience accumulation, has a full range of permanent magnet synchronous motor(PMSM) R & D capabilities, according to customer requirements for special design, can meet the needs of a variety of equipment.

2.The materials used are not the same

Our permanent magnet motor rotor permanent magnet material adopts high magnetic energy product and high endowment coercive force sintered NdFeB, conventional grades are N38SH, N38UH, N40UH, N42UH, etc. Our company promises that the annual demagnetization rate of the permanent magnets is not higher than 1‰.

The rotor lamination adopts high specification lamination materials such as 50W470, 50W270, and 35W270, with silicon steel sheets pressed together to reduce losses.

Molded coils all use sintered wire, high voltage resistance to withstand stronger, bulk winding all use corona 200 degrees of electromagnetic wire.

3.Rich in permnent magnet motor applications experiences can support alomost industrial loads

Our permanent magnet electric motor and alternators are used in iron and steel, coal, cement, chemical, petroleum, mining, metallurgy, building materials, rubber, textile, paper, transportation, electric power, medicine, metal calendering, food and beverage, water production and supply and other industrial and mining fields, with a wealth of use cases.