IE5 660-1140V TBVF Explosion-proof Low Speed Permanent Magnet Synchronous Motor

Product specification

| EX-mark | EX db I Mb |

| Rated voltage | 660,1140V... |

| Power range | 37-1250kW |

| Speed | 0-300rpm |

| Frequency | Variable frequency |

| Phase | 3 |

| Poles | By technical design |

| Frame range | 450-1000 |

| Mounting | B3,B35,V1,V3..... |

| Isolation grade | H |

| Protection grade | IP55 |

| Working duty | S1 |

| Customized | Yes |

| Production cycle | 30days |

| Origin | China |

Product features

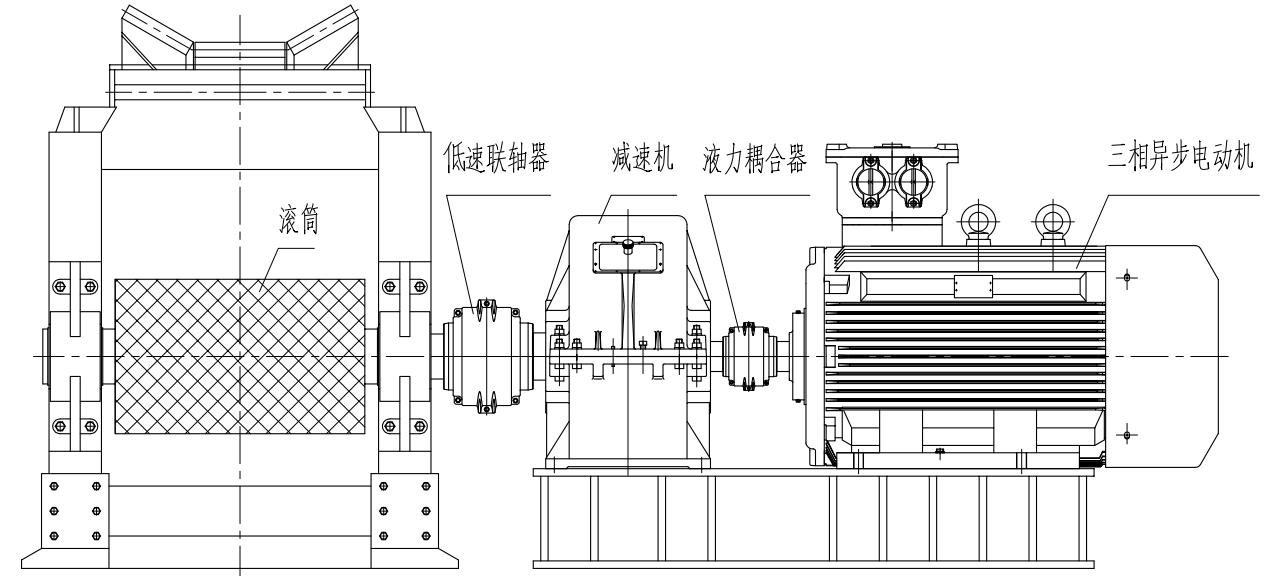

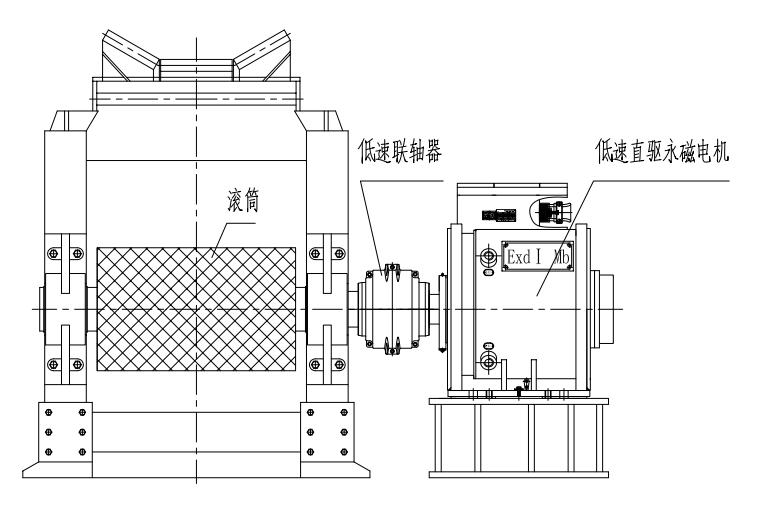

1. Eliminate the gearbox and hydraulic coupling. shorten the transmission chain. there is no problem of oil leakage and refuelling. low mechanical failure rate. high reliability.

2. Customised electromagnetic and structural design according to the equipment. which can directly meet the speed and torque requirements needed by the load;

3. Low starting current and low temperature rise. Eliminating the risk of demagnetisation;

4. eliminating the transmission efficiency loss of gearbox and hydraulic coupling. the system has high efficiency. high efficiency and energy saving. Simple structure. low operating noise and low daily maintenance costs;

5. The rotor part has a special support structure. which enables the bearing to be replaced on site. eliminating the logistics costs required for returning to the factory;

6. Adopting direct drive system of permanent magnet synchronous motor can solve the problem of "big horse pulling small cart". which can meet the requirement of wide load range operation of the original system. and improve the overall efficiency of the system. with high efficiency and energy saving;

7. Adopt vector frequency converter control. speed range 0-100%, starting performance is good. Stable operation. Can reduce the matching coefficient with the actual load power.

FAQ

What are the key points of low speed (rpm) motor selection?

1. On-site operating mode:

Such as load type, environmental conditions, cooling conditions, etc.

2. Original transmission mechanism composition and parameters:

Such as the nameplate parameters of the reducer, interface size, sprocket parameters, such as tooth ratio and shaft hole.

3. Intent to remodel:

Specifically whether to do direct drive or semi-direct drive, because the motor speed is too low, you must do closed-loop control, and some inverters do not support closed-loop control. In addition the motor efficiency is lower, while the motor cost is higher, the cost-effective is not high. The enhancement is the advantage of reliability and maintenance-free.

If cost and cost-effectiveness are more important, there are some conditions where a semi-direct-drive solution may be appropriate while ensuring reduced maintenance.

4. Controlling demand:

Whether the inverter brand is mandatory, whether the closed loop is required, whether the motor to the inverter communication distance should be equipped with an electronic control cabinet, what functions should the electronic control cabinet have, and what communication signals are required for remote DCS.

What is the main difference between the losses of permanent magnet motors of the same size compared to asynchronous motors?

Low stator copper consumption, low rotor copper consumption and Low rotor iron consumption.