Compared with asynchronous motors, permanent magnet synchronous motors have many obvious advantages. Permanent magnet synchronous motors have many features such as high power factor, good driving ability index, small size, light weight, low temperature rise, etc. At the same time, they can better improve the quality factor of the power grid, give full play to the capacity of the existing power grid, and save the investment of the power grid.

Efficiency and power factor comparison

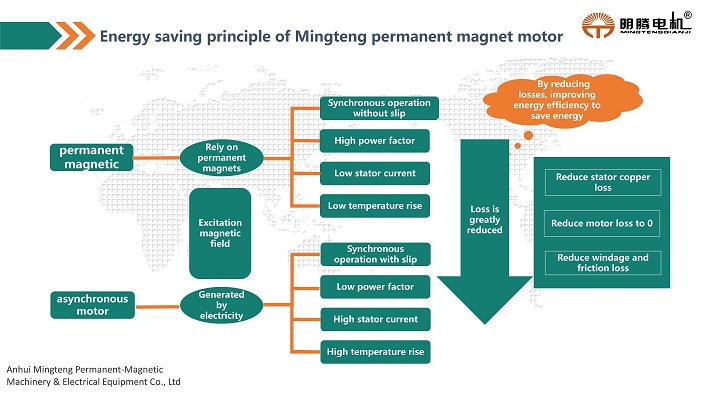

Asynchronous motor in the work, the rotor winding to absorb part of the power from the grid excitation, so that the consumption of grid power, this part of the power to the final current in the rotor winding in the heat consumed, the loss accounts for about 20-30% of the total loss of the motor, which directly leads to a reduction in the efficiency of the motor. Rotor excitation current converted to the stator winding is inductive current, so that the current into the stator winding lags behind the grid voltage, resulting in a reduction in the power factor of the motor.

In addition, asynchronous motor in the load factor (= P2 / Pn) < 50%, its operating efficiency and operating power factor drops significantly, so generally require it to operate in the economic zone, that is, the load rate of 75% -100%.

Permanent magnet synchronous motor in the rotor embedded in the permanent magnet, the permanent magnet to establish the rotor magnetic field, in normal operation, the rotor and stator magnetic field synchronous operation, no induced current in the rotor, there is no rotor resistance loss, only this one can improve the efficiency of the motor by 4% to 50%. At the same time, because there is no induction current excitation in the rotor of permanent magnet synchronous motor, the stator winding may be purely resistive load, so that the power factor of the motor is almost 1. Permanent magnet synchronous motor in the load rate > 20%, its operating efficiency and operating power factor with little change, and the operating efficiency is > 80%.

Starting torque

Asynchronous motor starting, the motor is required to have a large enough starting torque, but hope that the starting current is not too large, so as not to produce excessive voltage drop in the grid and affect the normal operation of other motors and electrical equipment connected to the grid. In addition, when the starting current is too large, the motor itself will be subjected to excessive electric force impact, if often start, there is a danger of overheating the windings. Therefore, asynchronous motor starting design is often faced with a dilemma.

Permanent magnet synchronous motor can also be used asynchronous starting mode, due to the permanent magnet synchronous motor normal operation of the rotor winding does not work, in the design of permanent magnet motor, the rotor winding can be made to fully meet the requirements of the high starting torque, for example, so that the starting torque multiplier by the asynchronous motor 1.8 times to 2.5 times, or even greater, a better solution to the conventional power equipment, It effectively solves the phenomenon of “big horses pulling small cart” in conventional power equipment.

Operation temperature rise

As the asynchronous motor work, the rotor winding current flow, and this current is completely in the form of thermal energy consumption, so in the rotor winding will produce a large amount of heat, so that the temperature of the motor rises, which seriously affects the service life of the motor.

As for the permanent magnet synchronous motor, due to the high efficiency of the permanent magnet motor, there is no resistance loss in the rotor winding, there is less or almost no reactive current in the stator winding, so that the motor temperature rise is low, which better extends the service life of the motor.

Influence on grid operation

Due to the low power factor of asynchronous motor, the motor needs to absorb a large amount of reactive current from the power grid, thus causing a large amount of reactive current in the power grid, transmission and transformation equipment and power generation equipment, thus making the quality factor of the power grid decrease, which not only aggravates the load of the power grid and transmission and transformation equipment and power generation equipment, at the same time, the reactive current consumes part of the electric power in the power grid, transmission and transformation equipment and power generation equipment, resulting in low efficiency and affecting the electric power grid. At the same time, the reactive current consumes part of the electric energy in the power grid, transmission and transformation equipment and power generation equipment, which causes the power grid to become less efficient and affects the effective utilization of electric energy. Similarly, due to the low efficiency of asynchronous motors, to meet the demand for output power, it is necessary to absorb more power from the grid, thus further increasing the loss of electrical energy and aggravating the load on the grid.

And for permanent magnet synchronous motor, its rotor without induction current excitation, motor power factor is also high, which not only improves the quality factor of the grid, so that the grid no longer need to install reactive power compensation equipment. Moreover, due to the high efficiency of the permanent magnet synchronous motor, it also saves the power of the grid

Anhui Mingteng Permanent-Magnetic Machinery&Electrical Equipment Co., Ltd was established in 2007 and is one of the earliest manufacturers in China to develop and produce permanent magnet motors. It has a comprehensive R&D, production, sales, and after-sales team. The company always adheres to independent innovation and adheres to the corporate policy of “first-class products, first-class management, first-class services, and first-class brands”, tailoring intelligent permanent magnet motor system energy-saving overall solutions for users, and striving to become a leader and standard setter in China’s rare earth permanent magnet motor industry.

Post time: Dec-11-2023