Introduction: When manufacturing explosion-proof motors, the choice of materials is very important, because the quality of the materials directly affects the performance and durability of the motor.

In the industrial field, explosion-proof motors are important equipment used to operate in dangerous environments, such as flammable gas, steam and dust. In these environments, there may be risks of explosion and fire. Therefore, explosion-proof motors must be able to effectively prevent sparks and heat generation to reduce the risk of explosion and fire.

When manufacturing explosion-proof motors, the choice of materials is very important because the quality of the material directly affects the performance and durability of the motor. The following are some key material properties that need to be considered when selecting explosion-proof motor materials:

Electrical conductivity:The material must have the proper conductivity to ensure that the motor’s electrical circuit can function properly.

Corrosion resistance:In hazardous environments, motors may be affected by corrosion. Therefore, the material must be corrosion resistant enough to maintain the performance of the motor.

High temperature resistance:When explosion-proof motors operate in high temperature environments, the materials must be able to withstand high temperatures to avoid overheating and failure of the motors.

Shock resistance:In a vibrating environment, the material must be able to resist the effects of vibration and shock to ensure the stability and reliability of the motor.

Explosion-proof:Explosion-proof motor materials must be able to effectively prevent the generation of sparks and heat, thereby reducing the risk of explosion and fire.

When selecting explosion-proof motor materials, it is necessary to consider the above material properties and select suitable materials according to the specific use environment and requirements. For example, some common explosion-proof motor materials include stainless steel, aluminum alloy, copper alloy, fiber material, ceramic material, etc. These materials have different properties and can be used in different hazardous environments to meet different needs.

In short, the selection of explosion-proof motor materials is very important. The quality of the materials directly affects the performance and durability of the motor. When selecting materials, it is necessary to consider the use environment and requirements, and select suitable materials to ensure the safe, stable and reliable operation of the motor. In addition, when manufacturing explosion-proof motors, in addition to the selection of materials, you also need to pay attention to the following aspects:

Design:The design of the motor must take into account the use in hazardous environments. For example, the motor housing must be equipped with explosion-proof doors to prevent the generation of sparks and heat.

Manufacturing process:The manufacturing process of the motor must comply with relevant safety standards and specifications. During the manufacturing process, attention must be paid to the testing and verification of explosion-proof performance to ensure the safety and reliability of the motor.

Care and maintenance:In the daily use of the motor, regular maintenance and care must be carried out to ensure the performance and safety of the motor. This includes cleaning, lubrication, and checking the circuit and wiring of the motor.

In conclusion, explosion-proof motors are very important for use in hazardous environments. They can effectively reduce the risk of explosions and fires. When manufacturing explosion-proof motors, choosing the right materials, designing a reasonable structure, strictly controlling the manufacturing process, and performing regular maintenance and care are all important factors in ensuring the safety and reliability of the motors. In addition to the factors mentioned above, there are some other factors that are also important, including:

Environment:The use environment of explosion-proof motors must comply with relevant safety standards and specifications. For example, in explosion-hazardous areas, appropriate explosion-proof facilities must be set up to ensure the safety of explosion-proof motors.

Motor Type:Different types of explosion-proof motors are suitable for different environments. For example, a paint room requires an anti-static motor, while a coal mine requires an explosion-proof motor.

Motor power:The power of explosion-proof motors must comply with relevant standards and specifications. The greater the power of the motor, the more safety factors need to be considered.

Safety measures:When using explosion-proof motors, a series of safety measures must be taken, such as using explosion-proof switches, explosion-proof cables, etc., to ensure the safety and reliability of the motors.

In short, the material selection of explosion-proof motors is one of the important factors to ensure the safety and reliability of motors, but it is not the only factor. When manufacturing, selecting and using explosion-proof motors, other relevant factors must also be taken into account to ensure the safety and reliability of motors, thereby effectively reducing the risk of explosion and fire.

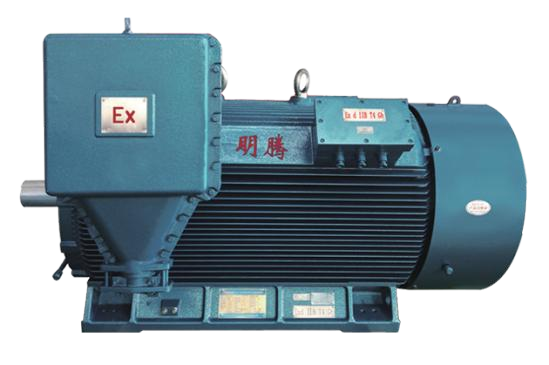

Anhui Mingteng Permanent-Magnetic Machinery & Electrical Equipment Co., Ltd(https://www.mingtengmotor.com/).can customize explosion-proof motor design according to different user needs. It has a full range of permanent magnet explosion-proof synchronous motors. The factory-use explosion-proof permanent magnet motor has obtained the explosion-proof certificate and the China National Compulsory Product Certification Certificate. The mine-use explosion-proof permanent magnet motor has obtained the explosion-proof certificate, the mining product safety mark certificate and the China National Compulsory Product Certification Certificate. The product has also passed the IEC Ex international certification, and can be certified for explosion-proof in other systems according to customer needs.

Copyright: This article is a reprint of the original link:

https://mp.weixin.qq.com/s/zlAu3-j7UR-lNnfYx_88Gw

This article does not represent our company’s views. If you have different opinions or views, please correct us!

Post time: Dec-20-2024