In the past few years, the motor industry when the high profile of permanent magnet motors, the degree of popularity shows a growing trend. According to analysis, the reason why permanent magnet motors can be doubly concerned, inseparable from the strong support of the relevant state policies to high-efficiency permanent magnet motors as a representative of high-efficiency, ultra-high-efficiency motor products can be quickly popularized to help energy saving and emission reduction, to retain green mountains and green water. Energy saving and environmental protection must be the future development trend, especially in the motor industry, permanent magnet motor energy-saving features show its advantages out of its energy-saving rate can be higher than 20%, on the rare earth permanent magnet motor energy-saving advantages are as follows:

Rare earth permanent magnet motor six energy-saving advantages

1, permanent magnet motor than ordinary motor energy saving 5%-30%, the specific equipment working conditions of different power saving rate is different.

2, permanent magnet synchronous motor to achieve a level of energy efficiency, energy efficiency of more than 95%; ordinary three-phase asynchronous motor is three energy efficiency, energy efficiency is only about 90%.

3, permanent magnet synchronous motor rotor has rare earth permanent magnet steel, do not need the stator to provide induction power, than ordinary motor loss is small;

4, permanent magnet synchronous motor stator lead wire is star (Y) connection, can keep the power unchanged current is small; ordinary motors are mostly △ connection;

5, permanent magnet synchronous motor in the operation process, when the load changes when the energy efficiency value can remain unchanged, ordinary asynchronous motor when the load changes when the energy efficiency value will change, ordinary asynchronous motor in the load up to three-quarters of the energy efficiency value is unchanged, when the load is less than 70% of the value of its energy efficiency will fall straight down.

6, permanent magnet synchronous motor no-load current is small, only one-tenth of the rated current, while the ordinary asynchronous motor in the no-load current to reach one-third.

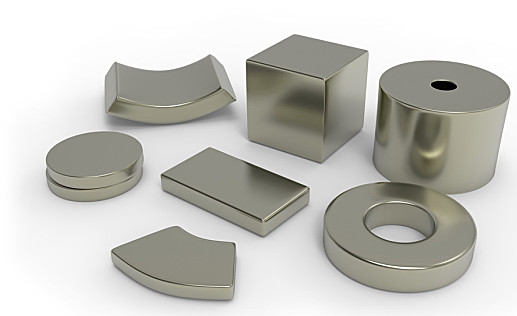

Rare earth permanent magnet motor three major components

1、Rare earth permanent magnet motor adopts high-performance permanent magnet, which eliminates the current excitation of the stator or rotor part of the motor, so it eliminates the copper loss of this part (winding heat loss);

2, the use of brushless structure, no carbon brush structure of the mechanical loss, but brushless motor is through the electronic commutation structure to realize the commutation, here there is a part of the electronic components of the loss, and save the mechanical loss compared to the loss value is small, so the commutation part of the loss than the loss of the brush motor loss is small;

3, the use of high-performance rare earth permanent magnets, in the same rated power and rated speed, the motor volume can be made smaller, saving the motor silicon steel sheet, reducing part of the iron loss. Small power motors using rare earth permanent magnet motor can reach close to 90% efficiency, the general motor is about 75%.

The use of PMSM has become a trend for enterprises to save energy, reduce emissions, and achieve win-win green development.

Post time: Nov-29-2023