With the development of rare earth permanent magnet materials in the 1970s, rare earth permanent magnet motors came into being. Permanent magnet motors use rare earth permanent magnets for excitation, and permanent magnets can generate permanent magnetic fields after magnetization. Its excitation performance is excellent, and it is superior to electric excitation motors in terms of stability, quality, and loss reduction, which has shaken the traditional motor market.

In recent years, with the rapid development of modern science and technology, the performance and technology of electromagnetic materials, especially rare earth electromagnetic materials, have gradually been improved. Coupled with the rapid development of power electronics, power transmission technology and automatic control technology, the performance of permanent magnet synchronous motors is getting better and better.

Furthermore, permanent magnet synchronous motors have the advantages of light weight, simple structure, small size, good characteristics and high power density. Many scientific research institutions and enterprises are actively carrying out the research and development of permanent magnet synchronous motors, and their application areas will be further expanded.

1.Development basis of permanent magnet synchronous motor

a.Application of high performance rare earth permanent magnet materials

Rare earth permanent magnet materials have gone through three stages: SmCo5, Sm2Co17, and Nd2Fe14B. Currently, permanent magnet materials represented by NdFeB have become the most widely used type of rare earth permanent magnet materials due to their excellent magnetic properties. The development of permanent magnet materials has driven the development of permanent magnet motors.

Compared with the traditional three-phase induction motor with electric excitation, the permanent magnet replaces the electric excitation pole, simplifies the structure, eliminates the slip ring and brush of the rotor, realizes the brushless structure, and reduces the size of the rotor. This improves the power density, torque density and working efficiency of the motor, and makes the motor smaller and lighter, further expanding its application field and promoting the development of electric motors towards higher power.

b.Application of new control theory

In recent years, control algorithms have developed rapidly. Among them, vector control algorithms have solved the driving strategy problem of AC motors in principle, making AC motors have good control performance. The emergence of direct torque control makes the control structure simpler, and has the characteristics of strong circuit performance for parameter changes and fast torque dynamic response speed. Indirect torque control technology solves the problem of large torque pulsation of direct torque at low speed, and improves the speed and control accuracy of the motor.

c.Application of high-performance power electronic devices and processors

Modern power electronics technology is an important interface between the information industry and traditional industries, and a bridge between weak current and controlled strong current. The development of power electronics technology enables the realization of drive control strategies.

In the 1970s, a series of general-purpose inverters appeared, which could convert industrial frequency power into variable frequency power with continuously adjustable frequency, thus creating conditions for variable frequency speed regulation of AC power. These inverters have soft start capability after the frequency is set, and the frequency can rise from zero to the set frequency at a certain rate, and the rising rate can be continuously adjusted within a wide range, solving the starting problem of synchronous motors.

2.Development status of permanent magnet synchronous motors at home and abroad

The first motor in history was a permanent magnet motor. At that time, the performance of permanent magnet materials was relatively poor, and the coercive force and remanence of permanent magnets were too low, so they were soon replaced by electric excitation motors.

In the 1970s, rare earth permanent magnet materials represented by NdFeB had great coercive force, remanence, strong demagnetization ability and large magnetic energy product, which made high-power permanent magnet synchronous motors appear on the stage of history. Now, the research on permanent magnet synchronous motors is becoming more and more mature, and is developing towards high speed, high torque, high power and high efficiency.

In recent years, with the strong investment of domestic scholars and the government, permanent magnet synchronous motors have developed rapidly. With the development of microcomputer technology and automatic control technology, permanent magnet synchronous motors have been widely used in various fields. Due to the progress of society, people's requirements for permanent magnet synchronous motors have become more stringent, prompting permanent magnet motors to develop towards a larger speed regulation range and higher precision control. Due to the improvement of current production processes, high-performance permanent magnet materials have been further developed. This greatly reduces its cost and gradually applies it to various fields of life.

3. Current technology

a. Permanent magnet synchronous motor design technology

Compared with ordinary electric excitation motors, permanent magnet synchronous motors have no electric excitation windings, collector rings and excitation cabinets, which greatly improves not only stability and reliability, but also efficiency.

Among them, built-in permanent magnet motors have the advantages of high efficiency, high power factor, high unit power density, strong weak magnetic speed expansion capability and fast dynamic response speed, making them an ideal choice for driving motors.

Permanent magnets provide the entire excitation magnetic field of permanent magnet motors, and cogging torque will increase the vibration and noise of the motor during operation. Excessive cogging torque will affect the low-speed performance of the motor speed control system and the high-precision positioning of the position control system. Therefore, when designing the motor, the cogging torque should be reduced as much as possible through motor optimization.

According to research, the general methods to reduce the cogging torque include changing the pole arc coefficient, reducing the slot width of the stator, matching the skew slot and pole slot, changing the position, size and shape of the magnetic pole, etc. However, it should be noted that when reducing the cogging torque, it may affect other performance of the motor, such as the electromagnetic torque may decrease accordingly. Therefore, when designing, various factors should be balanced as much as possible to achieve the best motor performance.

b.Permanent magnet synchronous motor simulation technology

The presence of permanent magnets in permanent magnet motors makes it difficult for designers to calculate parameters, such as the design of no-load leakage flux coefficient and pole arc coefficient. Generally, finite element analysis software is used to calculate and optimize the parameters of permanent magnet motors. Finite element analysis software can calculate motor parameters very accurately, and it is very reliable to use it to analyze the impact of motor parameters on performance.

The finite element calculation method makes it easier, faster and more accurate for us to calculate and analyze the electromagnetic field of motors. This is a numerical method developed on the basis of the difference method and has been widely used in science and engineering. Use mathematical methods to discretize some continuous solution domains into groups of units, and then interpolate in each unit. In this way, a linear interpolation function is formed, that is, an approximate function is simulated and analyzed using finite elements, which allows us to intuitively observe the direction of magnetic field lines and the distribution of magnetic flux density inside the motor.

c.Permanent magnet synchronous motor control technology

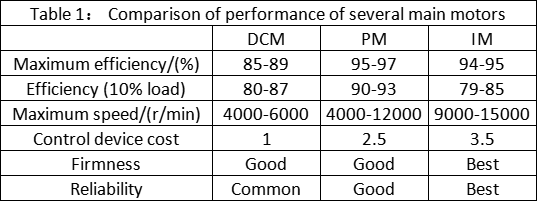

Improving the performance of motor drive systems is also of great significance to the development of the industrial control field. It enables the system to be driven at the best performance. Its basic characteristics are reflected in the low speed, especially in the case of rapid start-up, static acceleration, etc., it can output a large torque; and when driving at high speed, it can achieve constant power speed control in a wide range. Table 1 compares the performance of several major motors.

As can be seen from Table 1, permanent magnet motors have good reliability, wide speed range and high efficiency. If combined with the corresponding control method, the entire motor system can achieve the best performance. Therefore, it is necessary to select a suitable control algorithm to achieve efficient speed regulation, so that the motor drive system can operate in a relatively wide speed regulation area and constant power range.

The vector control method is widely used in the permanent magnet motor speed control algorithm. It has the advantages of wide speed regulation range, high efficiency, high reliability, good stability and good economic benefits. It is widely used in motor drive, rail transportation and machine tool servo. Due to different uses, the current vector control strategy adopted is also different.

4.Characteristics of permanent magnet synchronous motor

The permanent magnet synchronous motor has a simple structure, low loss and high power factor. Compared with the electric excitation motor, because there are no brushes, commutators and other devices, no reactive excitation current is required, so the stator current and resistance loss are smaller, the efficiency is higher, the excitation torque is larger, and the control performance is better. However, there are disadvantages such as high cost and difficulty in starting. Due to the application of control technology in motors, especially the application of vector control systems, permanent magnet synchronous motors can achieve wide range speed regulation, fast dynamic response and high-precision positioning control, so permanent magnet synchronous motors will attract more people to conduct extensive research.

5.Technical characteristics of Anhui Mingteng permanent magnet synchronous motor

a. The motor has a high power factor and a high quality factor of the power grid. No power factor compensator is required, and the capacity of the substation equipment can be fully utilized;

b. The permanent magnet motor is excited by permanent magnets and operates synchronously. There is no speed pulsation, and the pipeline resistance is not increased when driving fans and pumps;

c. The permanent magnet motor can be designed with high starting torque (more than 3 times) and high overload capacity as needed, thus solving The phenomenon of "big horse pulling small cart";

d. The reactive current of ordinary asynchronous motor is generally about 0.5-0.7 times of the rated current. Mingteng permanent magnet synchronous motor does not need excitation current. The reactive current of permanent magnet motor and asynchronous motor is about 50% different, and the actual operating current is about 15% lower than that of asynchronous motor;

e. The motor can be designed to start directly, and the external installation dimensions are the same as those of the currently widely used asynchronous motors, which can fully replace asynchronous motors;

f. Adding a driver can achieve soft start, soft stop, and stepless speed regulation, with good dynamic response and further improved power saving effect;

g. The motor has many topological structures, which directly meet the fundamental requirements of mechanical equipment in a wide range and under extreme conditions;

h. In order to improve system efficiency, shorten the transmission chain, and reduce maintenance costs, high and low speed direct drive permanent magnet synchronous motors can be designed and manufactured to meet the higher requirements of users.

Anhui Mingteng Permanent-Magnetic Machinery&Electrical Equipment Co., Ltd. (https://www.mingtengmotor.com/) was established in 2007. It is a high-tech enterprise specializing in the research and development, production and sales of ultra-high efficiency permanent magnet synchronous motors. The company uses modern motor design theory, professional design software and self-developed permanent magnet motor design program to simulate the electromagnetic field, fluid field, temperature field, stress field, etc. of the permanent magnet motor, optimize the magnetic circuit structure, improve the energy efficiency level of the motor, and fundamentally ensure the reliable use of the permanent magnet motor.

Copyright: This article is a reprint of the WeChat public number “Motor Alliance”, the original link https://mp.weixin.qq.com/s/tROOkT3pQwZtnHJT4Ji0Cg

This article does not represent our company’s views. If you have different opinions or views, please correct us!

Post time: Sep-14-2024