The development of permanent magnet motors is closely related to the development of permanent magnet materials. China is the first country in the world to discover the magnetic properties of permanent magnet materials and apply them in practice. More than 2,000 years ago, China used the magnetic properties of permanent magnet materials to make compasses, which played a huge role in navigation, military and other fields, and became one of the four great inventions of ancient China.

The first motor in the world, which appeared in the 1920s, was a permanent magnet motor that used permanent magnets to generate excitation magnetic fields. However, the permanent magnet material used at that time was natural magnetite (Fe3O4), which had a very low magnetic energy density. The motor made of it was large in size and was soon replaced by the electric excitation motor.

With the rapid development of various motors and the invention of current magnetizers, people have conducted in-depth research on the mechanism, composition and manufacturing technology of permanent magnetic materials, and have successively discovered a variety of permanent magnetic materials such as carbon steel, tungsten steel (maximum magnetic energy product of about 2.7 kJ/m3), and cobalt steel (maximum magnetic energy product of about 7.2 kJ/m3).

In particular, the appearance of aluminum nickel cobalt permanent magnets in the 1930s (maximum magnetic energy product can reach 85 kJ/m3) and ferrite permanent magnets in the 1950s (maximum magnetic energy product can reach 40 kJ/m3) have greatly improved magnetic properties, and various micro and small motors have begun to use permanent magnet excitation.The power of permanent magnet motors ranges from a few milliwatts to tens of kilowatts. They are widely used in military, industrial and agricultural production and daily life, and their output has increased dramatically.

Correspondingly, during this period, breakthroughs have been made in the design theory, calculation methods, magnetization and manufacturing technology of permanent magnet motors, forming a set of analysis and research methods represented by the permanent magnet working diagram diagram method. However, the coercive force of AlNiCo permanent magnets is low (36-160 kA/m), and the remanent magnetic density of ferrite permanent magnets is not high (0.2-0.44 T), which limits their application range in motors.

It was not until the 1960s and 1980s that rare earth cobalt permanent magnets and neodymium iron boron permanent magnets (collectively referred to as rare earth permanent magnets) came out one after another. Their excellent magnetic properties of high remanent magnetic density, high coercive force, high magnetic energy product and linear demagnetization curve are particularly suitable for manufacturing motors, thus ushering the development of permanent magnet motors into a new historical period.

1.Permanent magnetic materials

The permanent magnet materials commonly used in motors include sintered magnets and bonded magnets, the main types are aluminum nickel cobalt, ferrite, samarium cobalt, neodymium iron boron, etc.

Alnico: Alnico permanent magnet material is one of the earliest widely used permanent magnet materials, and its preparation process and technology are relatively mature.

Permanent ferrite: In the 1950s, ferrite began to flourish, especially in the 1970s, when strontium ferrite with good coercivity and magnetic energy performance was put into production in large quantities, rapidly expanding the use of permanent ferrite. As a non-metallic magnetic material, ferrite does not have the disadvantages of easy oxidation, low Curie temperature and high cost of metal permanent magnet materials, so it is very popular.

Samarium cobalt: A permanent magnet material with excellent magnetic properties that emerged in the mid-1960s and has very stable performance. Samarium cobalt is particularly suitable for manufacturing motors in terms of magnetic properties, but due to its high price, it is mainly used in the research and development of military motors such as aviation, aerospace, and weapons, and motors in high-tech fields where high performance and price are not the main factor.

NdFeB: NdFeB magnetic material is an alloy of neodymium, iron oxide, etc., also known as magnetic steel. It has extremely high magnetic energy product and coercive force. At the same time, the advantages of high energy density make NdFeB permanent magnet materials widely used in modern industry and electronic technology, making it possible to miniaturize, lighten and thin equipment such as instruments, electroacoustic motors, magnetic separation and magnetization. Because it contains a large amount of neodymium and iron, it is easy to rust. Surface chemical passivation is one of the best solutions at present.

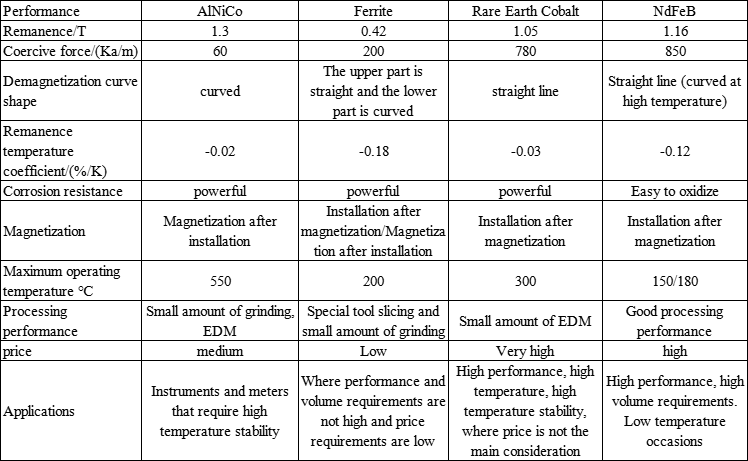

Corrosion resistance, maximum operating temperature, processing performance, demagnetization curve shape,

and price comparison of commonly used permanent magnet materials for motors (Figure)

2.The influence of magnetic steel shape and tolerance on motor performance

1. Influence of magnetic steel thickness

When the inner or outer magnetic circuit is fixed, the air gap decreases and the effective magnetic flux increases when the thickness increases. The obvious manifestation is that the no-load speed decreases and the no-load current decreases under the same residual magnetism, and the maximum efficiency of the motor increases. However, there are also disadvantages, such as increased commutation vibration of the motor and a relatively steeper efficiency curve of the motor. Therefore, the thickness of the motor magnetic steel should be as consistent as possible to reduce vibration.

2.Influence of magnetic steel width

For closely spaced brushless motor magnets, the total cumulative gap cannot exceed 0.5 mm. If it is too small, it will not be installed. If it is too large, the motor will vibrate and reduce efficiency. This is because the position of the Hall element that measures the position of the magnet does not correspond to the actual position of the magnet, and the width must be consistent, otherwise the motor will have low efficiency and large vibration.

For brushed motors, there is a certain gap between the magnets, which is reserved for the mechanical commutation transition zone. Although there is a gap, most manufacturers have strict magnet installation procedures to ensure the installation accuracy in order to ensure the accurate installation position of the motor magnet. If the width of the magnet exceeds, it will not be installed; if the width of the magnet is too small, it will cause the magnet to be misaligned, the motor will vibrate more, and the efficiency will be reduced.

3.The influence of magnetic steel chamfer size and non-chamfer

If the chamfer is not done, the rate of change of the magnetic field at the edge of the motor's magnetic field will be large, causing the motor's pulsation. The larger the chamfer, the smaller the vibration. However, chamfering generally causes a certain loss in magnetic flux. For some specifications, the magnetic flux loss is 0.5~1.5% when the chamfer is 0.8. For brushed motors with low residual magnetism, appropriately reducing the size of the chamfer will help compensate for the residual magnetism, but the motor's pulsation will increase. Generally speaking, when the residual magnetism is low, the tolerance in the length direction can be appropriately enlarged, which can increase the effective magnetic flux to a certain extent and keep the motor's performance basically unchanged.

3.Notes on permanent magnet motors

1. Magnetic circuit structure and design calculation

In order to give full play to the magnetic properties of various permanent magnet materials, especially the excellent magnetic properties of rare earth permanent magnets, and manufacture cost-effective permanent magnet motors, it is not possible to simply apply the structure and design calculation methods of traditional permanent magnet motors or electromagnetic excitation motors. New design concepts must be established to re-analyze and improve the magnetic circuit structure. With the rapid development of computer hardware and software technology, as well as the continuous improvement of modern design methods such as electromagnetic field numerical calculation, optimization design and simulation technology, and through the joint efforts of the motor academic and engineering communities, breakthroughs have been made in the design theory, calculation methods, structural processes and control technologies of permanent magnet motors, forming a complete set of analysis and research methods and computer-aided analysis and design software that combines electromagnetic field numerical calculation and equivalent magnetic circuit analytical solution, and is being continuously improved.

2. Irreversible demagnetization problem

If the design or use is improper, the permanent magnet motor may produce irreversible demagnetization, or demagnetization, when the temperature is too high (NdFeB permanent magnet) or too low (ferrite permanent magnet), under the armature reaction caused by the impact current, or under severe mechanical vibration, which will reduce the performance of the motor and even make it unusable. Therefore, it is necessary to study and develop methods and devices suitable for motor manufacturers to check the thermal stability of permanent magnet materials, and to analyze the anti-demagnetization capabilities of various structural forms, so that corresponding measures can be taken during design and manufacturing to ensure that the permanent magnet motor does not lose magnetism.

3.Cost Issues

Since rare earth permanent magnets are still relatively expensive, the cost of rare earth permanent magnet motors is generally higher than that of electric excitation motors, which needs to be compensated by its high performance and savings in operating costs. In some occasions, such as voice coil motors for computer disk drives, the use of NdFeB permanent magnets improves performance, significantly reduces volume and mass, and reduces total costs. When designing, it is necessary to make a comparison of performance and price based on specific usage occasions and requirements, and to innovate structural processes and optimize designs to reduce costs.

Anhui Mingteng Permanent Magnet Electromechanical Equipment Co., Ltd. (https://www.mingtengmotor.com/). The demagnetization rate of permanent magnet motor magnetic steel is no more than one thousandth per year.

The permanent magnet material of the permanent magnet motor rotor of our company adopts high magnetic energy product and high intrinsic coercivity sintered NdFeB, and the conventional grades are N38SH, N38UH, N40UH, N42UH, etc. Take N38SH, a commonly used grade of our company, as an example: 38- represents the maximum magnetic energy product of 38MGOe; SH represents the maximum temperature resistance of 150℃. UH has a maximum temperature resistance of 180℃. The company has designed professional tooling and guide fixtures for magnetic steel assembly, and qualitatively analyzed the polarity of the assembled magnetic steel with reasonable means, so that the relative magnetic flux value of each slot magnetic steel is close, which ensures the symmetry of the magnetic circuit and the quality of magnetic steel assembly.

Copyright: This article is a reprint of the WeChat public number “today's motor”, the original link https://mp.weixin.qq.com/s/zZn3UsYZeDwicEDwIdsbPg

This article does not represent our company’s views. If you have different opinions or views, please correct us!

Post time: Aug-30-2024