Comprehensive Benefit Analysis of Replacing Asynchronous Motors with Permanent Magnet Synchronous Motors.

We start from the characteristics of permanent magnet synchronous motor, combined with the practical application to explain the comprehensive benefits of promoting permanent magnet synchronous motor.

Synchronous motor relative to asynchronous motor, the advantages of high power factor, high efficiency, rotor parameters can be measured, large stator-rotor air gap, good control performance, small size, light weight, simple structure, high torque / inertia ratio, etc., in the petroleum, chemical industry, light textile, mining, CNC machine tools, robots and other fields has been increasingly widely used, and to high-power (high speed, high torque), highly functional and Miniaturization.

The permanent magnet synchronous motor consists of a stator and a rotor. The stator is the same as an asynchronous motor and consists of three-phase windings and a stator core. The stator is the same as the asynchronous motor, which consists of three windings and stator core. The rotor is equipped with pre-magnetized (magnetized) permanent magnets, which can establish a magnetic field in the surrounding space without external energy, simplifying the structure of the motor and saving energy.

Outstanding advantages of permanent magnet synchronous motor

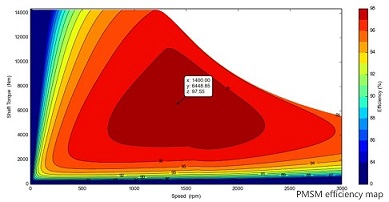

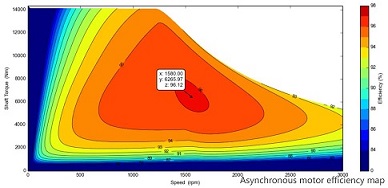

(1) Since the rotor is made of permanent magnets, the magnetic flux density is high and no excitation current is needed, thus eliminating the excitation loss. Compared with the asynchronous motor, it reduces the excitation current of the stator side winding and the copper and iron loss of the rotor side, and greatly reduces the reactive current. Due to the synchronization of the stator and rotor potentials, there is no fundamental iron loss in the rotor core, so the efficiency (in relation to the active power) and power factor (in relation to the reactive power) are higher than that of the asynchronous motor. Permanent magnet synchronous motors are generally designed to have higher power factor and efficiency even at light load operation.

(2) Permanent magnet synchronous motors have hard mechanical characteristics and strong resistance to motor torque disturbances caused by load changes. The rotor core of a permanent magnet synchronous motor can be made into a hollow structure to reduce rotor inertia, and the start and stop times are much faster than asynchronous motors. The high torque/inertia ratio makes permanent magnet synchronous motors more suitable for operation under fast response conditions than asynchronous motors.

(3) The size of permanent magnet synchronous motors is significantly reduced compared to asynchronous motors, and their weight is also relatively reduced. The power density of permanent magnet synchronous motors with the same heat dissipation conditions and insulation materials is more than twice that of three-phase asynchronous motors.

(4) The rotor structure is greatly simplified, easy to maintain, and improves the stability of operation.

(5) Due to the high power factor required for the design of three-phase asynchronous motors, it is necessary to keep the air gap between the stator and rotor very small. At the same time, the uniformity of the air gap is also crucial for the safe operation and vibration noise of the motor. Therefore, asynchronous motors have relatively strict requirements for the shape and position tolerance of components and assembly concentricity, and there are relatively few degrees of freedom for selecting bearing clearance. Large frame asynchronous motors usually use bearings lubricated by oil baths, It is necessary to add lubricating oil within the specified working hours. Oil leakage or untimely filling in the oil chamber can accelerate bearing failure. In the maintenance of three-phase asynchronous motors, bearing maintenance accounts for a large proportion. In addition, due to the presence of induced current in the rotor of three-phase asynchronous motors, the issue of electrical corrosion of bearings has also been of concern to many researchers in recent years.

(6) Permanent magnet synchronous motors do not have such problems. The related problems caused by the large air gap of permanent magnet synchronous motors and the small air gap of the above asynchronous motors are not obvious on synchronous motors. At the same time, the bearings of permanent magnet synchronous motors use grease lubricated bearings with dust covers. The bearings are sealed with an appropriate amount of high-quality lubricating grease at the factory, which can be maintenance free for life.

Epilogue

From the perspective of economic benefits, permanent magnet synchronous motors are particularly suitable for heavy start and light operation scenarios. Promoting the use of permanent magnet synchronous motors has positive economic and social benefits, and is of great significance for energy conservation and emission reduction. In terms of reliability and stability, permanent magnet synchronous motors also have valuable advantages. Choosing high-efficiency permanent magnet synchronous motors is a one-time investment and long-term benefit process.

After 16 years of technological accumulation, Anhui Mingteng Permanent-Magnetic Machinery&Electrical Equipment Co., Ltd has the R&D capability for a full range of permanent magnet motors, covering various industries such as steel, cement, and coal mines, and can meet the needs of various working conditions and equipment. Compared to asynchronous motors of the same specification, the company’s products have higher efficiency, wider economic operating range, and significant energy-saving effects. We look forward to more and more enterprises using permanent magnet motors as soon as possible to reduce consumption and increase production!

Post time: Nov-08-2023