1.Scope of application

Suitable for belt conveyor in mining, coal, metallurgy and other industries.

2.Technical principle and process

The shell of the permanent magnet direct-drive drum motor is the outer rotor, the rotor adopts magnets inside to form the magnetic circuit, the stator coil is fixed on the rotor shaft quill, the coil leads are introduced into the junction box through the internal threading holes of the rotor shaft, the power supply leads are connected to the junction box, and there are also the main parts of the corresponding support such as the end cover, standoffs, bearings, and oil cover, as well as the standard parts such as sealing, fastening, etc. The drum is driven by the frequency converter drive, and the drive efficiency rises dramatically. It realizes high efficiency, high torque and low speed synchronous drive.

3. Technical and Functional Characteristics

(1) The drum motor shell is used as the rotor, eliminating the intermediate reduction mechanism, realizing gearless transmission, saving a lot of space, facilitating installation and maintenance, and significantly improving the efficiency of the transmission system, with energy savings of 5%-20% compared with the traditional transmission motors;

(2) Optimize the design of drum motor rotor, stator, stator shaft, cooling mechanism and other structures to reduce noise, reduce vibration and improve heat dissipation performance;

(3) Through the master-slave control of frequency converter, it realizes soft start and frequency conversion speed regulation of drum motor, reduces the start-up impact, and has obvious energy-saving effect. At the same time can realize multi-motor balance control, reduce conveyor belt stress, improve equipment safety, reduce maintenance costs.

(4) High efficiency power factor, in the 20%-120% load range can always maintain efficient operation, the power factor will not be reduced.

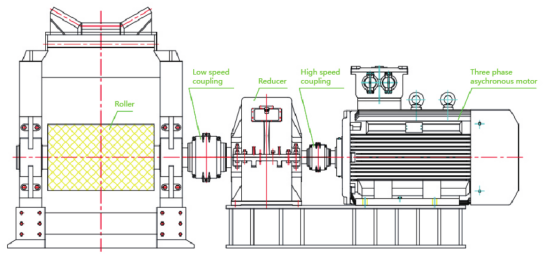

The traditional power configuration of the belt conveyor is an asynchronous motor through a gear reducer, decelerating and increasing the torque, which drives the drive pulley to rotate and drive the belt conveyor to run, as follows.

Conventional power configuration of belt conveyor

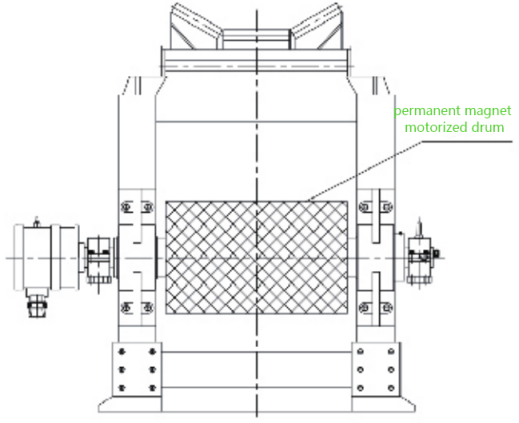

The original drive system is replaced by a permanent magnet synchronous motor direct drive system with permanent magnet drum motor + vector frequency converter. The permanent magnet synchronous motor direct drive system consists of a low-speed permanent magnet pulley and a special frequency converter for the permanent magnet motor, and the vector control function of the frequency converter meets the operating requirements of the low-speed equipment. This system replaces the original inverter + general asynchronous motor + fluid coupling + reduction mechanism, and the permanent magnet drum is directly connected to the load, which simplifies the transmission chain and realizes the energy saving of the whole system through the high efficiency of the permanent magnet drum and the improvement of the efficiency of the transmission system. At the same time, the liquid coupler and reducer are canceled, eliminating the mechanical failure and oil leakage problems that are prone to occur during its operation.

Permanent magnet direct drive drum power configuration

User's side site photo

User's side site photo

User's side site photos

User's side site photos

Since the introduction of the "14th Five-Year Plan" Carbon Peak and Carbon Neutral Plan, China will strictly control coal power projects, strictly control the growth of coal consumption, and gradually reduce it in the "15th Five-Year Plan" period. In addition, China has decided to accept the Kigali Amendment to the Montreal Protocol, to strengthen the control of non-carbon dioxide greenhouse gases, but also to start the national carbon market on-line trading.

Energy saving and emission reduction is the key to the development of all walks of life, this time, a variety of energy-saving and environmentally friendly products are more widely used, the prospects are brighter. Benefit from the global energy saving and emission reduction, green environmental protection and other strategies to pull, permanent magnet drum motor market potential in the next few years is very large.

Anhui Mingteng Permanent-Magnetic Machinery &Electrical Equipment Co., Ltd independently researches and develops and produces permanent magnetic direct-drive pulleys, which provide more efficient and stable power support for the transmission equipment of various mines, coal, metallurgy and other enterprises. Professional program design, meticulous product production, perfect after-sales service makes Minteng in the field of permanent magnetic drum has gained a good reputation, looking forward to more industrial and mining enterprises can use permanent magnetic drum motor.

Post time: Mar-15-2024