China’s National Development and Reform Commission and other nine departments jointly issued the “motor upgrading and recycling implementation guide (2023 edition)” (hereinafter referred to as “implementation guide”), “implementation guide” clear objectives, put forward to enhance the supply capacity of energy efficient motors, the implementation of energy-saving carbon-reducing transformation of the motor, eliminating inefficient and backward motors, and strengthen the development and application of cutting-edge technology and other work initiatives. Among the five tasks on the ground, the keyword “low-speed direct-drive motors” is mentioned, and you will have the same question: what are the low-speed direct-drive motors that are actively promoted by the state? Why is it being promoted?

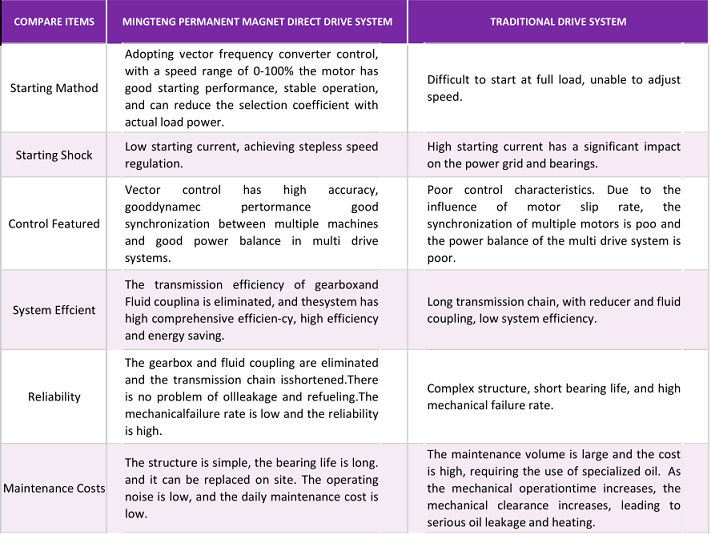

The low-speed direct-drive motors in the Implementation Guidelines should refer to low-speed high-torque permanent magnet direct-drive motors. Currently, there is no strict definition of low-speed and high-torque permanent magnet direct-drive motor, which generally refers to a new type of synchronous motor with a rotational speed lower than 500r/min, a torque greater than 500N-m, no reduction gear device, and a low rotational speed obtained directly from the motor. Driven by the goal of “dual-carbon strategy”, it is an important topic to explore how to improve the energy-saving, environmental protection and stable performance of the motor system. At present, the widely used motor system transmission device is the mode of induction motor + reducer, induction motor due to the existence of stator resistance and stator current loss, stable operation of the wind abrasion also occupies a certain proportion of these factors limit the improvement of the power factor; the existence of the reducer reduces the efficiency of the transmission, the existence of the structure is complex, easy to wear the reducer mechanism, the lubricant leakage, high maintenance costs and the system overall Low efficiency and other shortcomings, does not meet the requirements of economic development, energy saving and environmental protection. Low-speed high-torque permanent magnet direct-drive motors have the common characteristics of permanent magnet motors, such as long service life, easy maintenance, energy saving and environmental protection.

At present, due to the low-speed permanent magnet synchronous motor has the advantages of low speed and high torque, smaller volume than the same power motor + reducer, smooth output, high efficiency and energy saving, etc., it is used as a driving device in many fields, such as: mining, coal, cement, metallurgy, petroleum, chemical industry, water conservancy engineering field of application of the belt conveyor, scraper, bucket wheel machine, ball mill, lifting machinery, open refining machine, refining machine, extruders, vacuum pumps, reciprocating compressors, vacuum pumps, and vacuum compressors,vacuum pumps, reciprocating compressors, low head, large flow rate of low-speed pumps and so on. As we all know, mining, coal, cement, metallurgy, petroleum, chemical industry is a high energy consumption, high pollution industry, and currently similar to the belt conveyor, elevator, ball mill and other heavy machinery and equipment are mainly used in induction motors, speed reducers and the size of the open gear drive mode, the penetration of low-speed, high-torque PM motors is low, with the government of China’s sustained transformation and upgrading of the industry and the energy-saving transformation requirements With the continuous transformation and upgrading of the above industries by the Chinese government and the requirements for energy-saving transformation, the demand for low-speed high-torque permanent magnet motors in these industries may grow, and the market size of low-speed high-torque permanent magnet motors will show a stable growth trend.

Mingteng low rpm direct-drive motors https://www.mingtengmotor.com/ have a wide range of applications in various industries, a wealth of cases, mature technology, the company has always maintained the pioneering spirit of continuous innovation, now the lowest speed can be done to 7.5rpm, to reach the industry’s leading level, It is the preferred driving device for low-speed loads.

Post time: Jan-08-2024