The fan is a ventilation and heat dissipation device matched with the variable frequency motor,According to the structural characteristics of the motor, there are two types of fans: axial flow fans and centrifugal fans;The axial flow fan is installed at the non-shaft extension end of the motor, which is functionally equivalent to the external fan and wind cover of the industrial frequency motor; while the centrifugal fan is installed at the appropriate position of the motor according to the motor body structure and the specific functions of some additional devices.

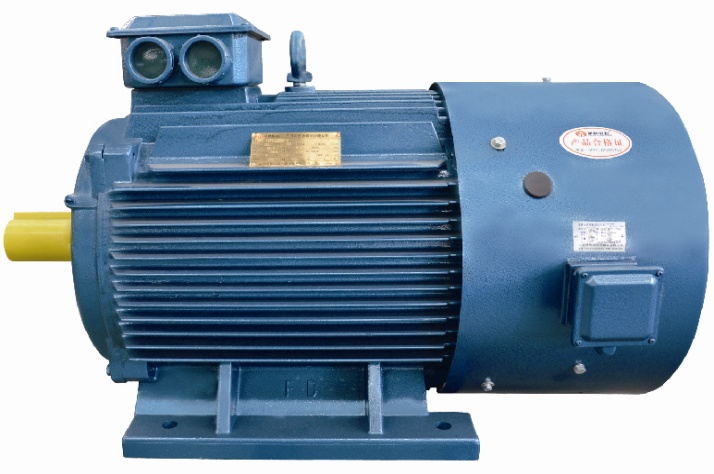

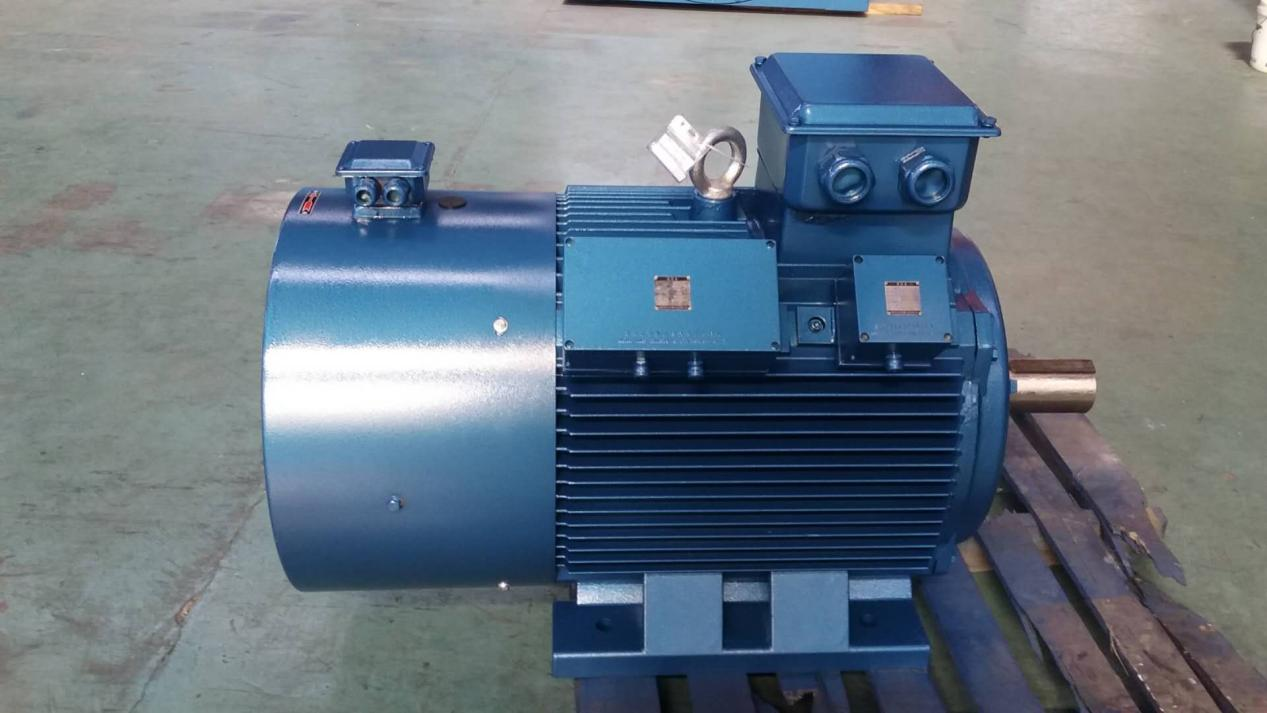

TYPCX series variable frequency permanent magnet synchronous motor

For the case where the motor frequency variation range is small and the motor temperature rise margin is large, the built-in fan structure of the industrial frequency motor can also be used. For the case where the motor operating frequency range is wide, an independent fan should be installed in principle. The fan is called an independent fan because of its relative independence from the mechanical part of the motor and the relative independence of the fan power supply and the motor power supply, that is, the two cannot share a set of power supplies.

The variable frequency motor is powered by a variable frequency power supply or inverter, and the motor speed is variable. The structure with a built-in fan cannot meet the heat dissipation requirements of the motor at all operating speeds, especially when running at low speed, which leads to an imbalance between the heat generated by the motor and the heat taken away by the cooling medium air with a seriously insufficient flow rate. That is, the heat generation remains unchanged or even increases, while the air flow that can carry heat is sharply reduced due to the low speed, resulting in heat accumulation and inability to dissipate, and the winding temperature rises rapidly or even burns the motor. An independent fan that is unrelated to the motor speed can meet this demand:

(1) The speed of the independently operated fan is not affected by the speed change during the operation of the motor. It is always set to start before the motor and lag behind the motor shutdown, which can better meet the ventilation and heat dissipation requirements of the motor.

(2) The power, speed and other parameters of the fan can be appropriately adjusted in combination with the design temperature rise margin of the motor. The fan motor and the motor body can have different poles and different voltage levels when conditions permit.

(3) For structures with many additional components of the motor, the design of the fan can be adjusted to meet the ventilation and heat dissipation requirements while minimizing the overall size of the motor.

(4) For the motor body, due to the lack of a built-in fan, the mechanical loss of the motor will be reduced, which has a certain effect on improving the efficiency of the motor.

(5) From the analysis of the vibration and noise index control of the motor, the overall balance effect of the rotor will not be affected by the later installation of the fan, and the original good balance state will be maintained; as for the motor noise, the noise performance level of the motor can be improved overall through the low noise design of the fan.

(6) From the structural analysis of the motor, due to the independence of the fan and the motor body, it is relatively easier to maintain the motor bearing system or disassemble the motor for inspection than a motor with a fan, and there will be no interference between the different axes of the motor and the fan.

However, from the perspective of manufacturing cost analysis, the cost of the fan is significantly higher than that of the fan and the hood, but for variable frequency motors that operate in a wide speed range, an axial flow fan must be installed. In the failure cases of variable frequency motors, some motors have winding burnout accidents due to the failure of the axial flow fan to work, that is, during the operation of the motor, the fan is not started in time or the fan fails, and the heat generated by the motor operation cannot be dissipated in time, causing the winding to overheat and burn.

For variable frequency motors, especially those using variable frequency drives for speed regulation, because the power waveform is not a normal sine wave but a pulse width modulation wave, the steep impact pulse wave will continuously corrode the winding insulation, causing insulation aging or even breakdown. Therefore, variable frequency motors are more likely to have problems during operation than ordinary industrial frequency motors, and special electromagnetic wires for variable frequency motors must be used, and the winding withstand voltage assessment value must be increased.

The three major technical characteristics of fans, variable frequency speed regulation, and resistance to shock pulse waves in the power supply determine the excellent operating characteristics and insurmountable technical barriers of variable frequency motors that are different from ordinary motors. In practical applications, the threshold for simple and extensive application of variable frequency motors is very low, or it can be achieved by installing an independent fan, but the variable frequency motor system composed of fan selection and its interface with the motor, wind path structure, insulation system, etc. covers a wide range of technical fields. There are many restrictive factors for high-efficiency, high-precision and environmentally friendly operation, and many technical barriers must be overcome, such as the howling problem when operating in a certain frequency band, the problem of electrical corrosion of bearing shaft current, and the problem of electrical reliability during variable frequency power supply, all of which involve deeper technical problems.

The professional technical team of Anhui Mingteng Permanent-Magnetic Machinery & Electrical Equipment Co., Ltd.(https://www.mingtengmotor.com/) uses modern motor design theory, professional design software and self-developed permanent magnet motor design program to simulate the electromagnetic field, fluid field, temperature field, stress field, etc. of the permanent magnet motor, thereby ensuring the efficient operation of the variable frequency motor.

Copyright: This article is a reprint of the original link:

https://mp.weixin.qq.com/s/R5UBzR4M_BNxf4K8tZkH-A

This article does not represent our company’s views. If you have different opinions or views, please correct us!

Post time: Dec-13-2024