Anhui Mingteng Permanent-Magnetic Machinery &Electrical Equipment Co., Ltd., as a leading enterprise in the permanent magnet motor industry, was established on October 18th, 2007. It is a modern high-tech enterprise that integrates the research and development, manufacturing, sales, and service of permanent magnet motors.

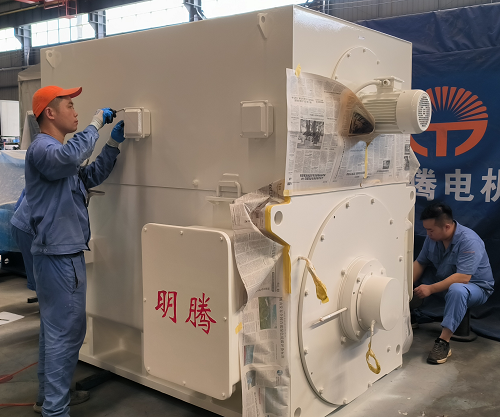

In August 2023, our company exported a variable frequency permanent magnet motor to Thailand and completed delivery by the end of August. This is the first time that our company’s permanent magnet synchronous motor with a power of over 2000 kilowatts has been exported and put into use abroad, indicating that our company’s application, research and development, and technical strength in the industrial field of permanent magnet synchronous motors are at a leading level both domestically and internationally.

Customer: Zhongce Rubber (Thailand) Co., Ltd

Model: TYPKS560-6 10KV 1000rpm IC86W

Power: 2240KW

Load: Mixer

After fully understanding the working characteristics and environment of the rubber industry mixer, the company strictly follows customer requirements and technical specifications, and independently develops and completes production. Technically adopted:

(1) Optimize electromagnetic design, select high-performance silicon steel sheets for the stator and rotor core materials, suppress high-frequency iron loss, and improve efficiency;

(2) Adopting a rolling bearing structure, it has a large load capacity and high reliability, which improves the load capacity of the motor. An internal support structure has been designed for the motor, making it easy to install and disassemble bearings and easy to maintain.

(3) Selected slot matching, optimized stator slot ratio, effectively reducing motor slot torque and reducing motor noise;

(4) Adopting IC86W cooling method to enhance cooling effect and effectively reduce motor temperature rise.

The above greatly ensures the efficiency, working performance, and stability of the motor.

Our company dispatched technical personnel to Thailand for installation and debugging according to customer requirements, and the equipment is currently running well with high customer satisfaction. In this project, compared to the original drive system, it not only improves efficiency, but also uses a frequency converter to cooperate with startup to achieve stepless speed regulation, reduce equipment impact, and can also adjust the speed according to the working conditions, resulting in significant energy-saving effects.

Mingteng permanent magnet synchronous motor(https://www.mingtengmotor.com/products/) uses a permanent magnet to provide the magnetic field required for electromechanical energy conversion, without the need for an excitation power source. During synchronous operation, there is almost no current in the rotor, so the copper loss of the rotor is close to zero, and the power factor is greatly improved compared to asynchronous motors. The reactive current in the stator winding is small, and the stator copper loss is reduced. Under the same conditions, the efficiency of permanent magnet synchronous motors is higher than that of asynchronous motors. The actual operating current of permanent magnet synchronous motors is more than 15% lower than that of asynchronous motors. Compared with three-phase asynchronous motors of the same power and speed, the temperature rise is reduced by about 20K, the power factor reaches 0.96 or above, and the rated efficiency is increased by 1% to 8% or even higher than that of three-phase asynchronous motors. The efficiency index meets or exceeds the IE5 standard. Currently, more than 300 enterprises have chosen Mingteng permanent magnet motors as the driving equipment for consumption reduction and production improvement.

We believe that Mingteng permanent magnet motor, with its energy-saving and maintenance free advantages, will also be favored by more abroad enterprises in the future, and will shine even more brightly on the stage of the driving industry.

Post time: Dec-29-2023