Recently, the 2500kW 132rpm 10kV dust explosion-proof low-speed direct-drive permanent magnet synchronous motor for coal mill designed and developed by our company has been successfully put into operation in a cement group's 6,000-ton-per-day intelligent and environmentally friendly clinker cement production line project, which marks another major progress in the direction of our permanent magnet motor technology.

Project Overview

(1) Project name: 6000 tons per day intelligent and environmentally friendly clinker cement production line (reduction and replacement) project of Bijie Certain Cement Co.

(2) Bijie City, Guizhou Province

(3) Construction scale: a 6000t/d clinker new dry-process cement production line and its supporting waste heat power generation system (clinker stable production capacity: 7500t/d)

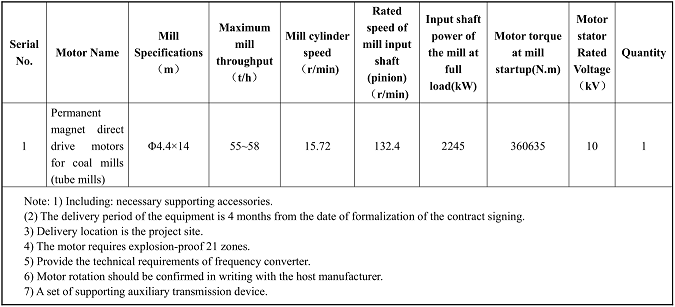

Equipment Requirements

Technical specification

1. Vacuum pressure dipping paint and epoxy resin vacuum potting dual process standards are adopted to meet the needs of improving the overall strength of the coil, improving the moisture and waterproof performance of the coil, preventing corona phenomenon from occurring, and improving the cooling capacity after epoxy resin vacuum potting.

2. The maximum demagnetization temperature of the permanent magnet material is not less than 180℃, and the annual demagnetization rate does not exceed 0.1%.

3. Rated short-time frequency resistance of 12kV.

4. The stator coil adopts centralized winding, and the enameled wire adopts H-class insulation, which has strong overload capacity and high safety and reliability.

5. The outer shell of the motor adopts steel plate integrated welding parts, which ensures the electrical and mechanical strength as well as good corrosion and moisture resistance.

6. The motor bearings adopt imported full-sealed maintenance-free rolling bearings.

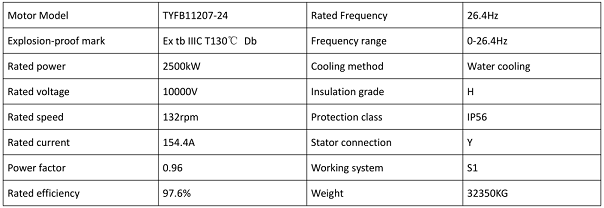

Motor parameters

Our company service personnel on-site commissioning, the dust explosion-proof low-speed direct-drive motors on-site use of good results, the owners of the unit is satisfied.

If you have a need for low-speed motors, please contact our company https://www.mingtengmotor.com/products/to create a tailor-made drive solution for the working conditions, saving power, reducing costs and increasing production.

Post time: Jul-08-2024