In daily life, from electric toys to electric cars, electric motors can be said to be everywhere. These motors come in various types such as brushed DC motors, brushless DC (BLDC) motors, and permanent magnet synchronous motors (PMSM). Each type has its unique characteristics and differences, making them suitable for different applications.

Let’s start with brushed DC motors. These motors have been around for a long time and are widely used in applications where simplicity and cost-effectiveness are crucial factors. Brushed DC motors use brushes and a commutator to supply power to the motor’s rotor. However, these brushes tend to wear out over time, resulting in reduced efficiency and reliability. Additionally, brushed DC motors produce a lot of electrical noise due to the brushes’ constant contact with the commutator, limiting their use in certain applications.

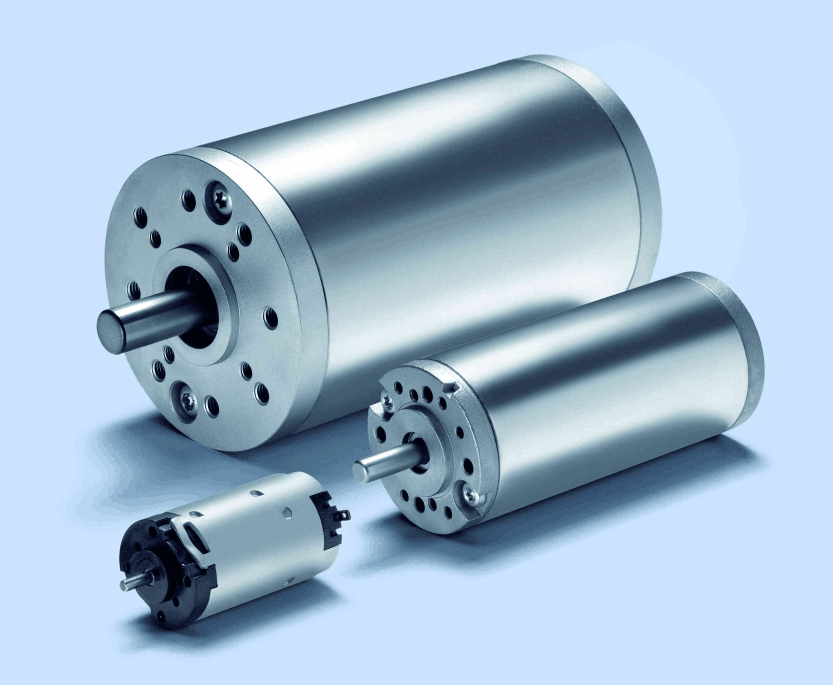

On the other hand, BLDC motors, as the name suggests, do not use brushes for commutation. Instead, they employ electronically controlled switching devices to control the motor’s phase currents. This brushless design offers several advantages over brushed DC motors. Firstly, BLDC motors are more reliable and have higher efficiency since there are no brushes to wear out. This improvement in efficiency translates into energy savings and increased battery life in portable applications. Moreover, the absence of brushes eliminates electrical noise, allowing for quieter operation, making BLDC motors ideal for applications where noise is a critical factor, such as electric vehicles and drones.

When it comes to PMSM, they share similarities with BLDC motors but have slight differences in their construction and control. PMSM motors also utilize permanent magnets in the rotor, similar to BLDC motors. However, PMSM motors have a sinusoidal back-EMF waveform, whereas BLDC motors have a trapezoidal waveform. This difference in waveform affects the control strategy and performance of the motors.

PMSM motors offer several advantages over BLDC motors. The sinusoidal back-EMF waveform inherently produces smoother torque and operation, resulting in reduced cogging and vibration. This makes PMSM motors ideal for applications requiring high precision and smooth operation, such as robotics and industrial machinery. Additionally, PMSM motors have a higher power density, meaning they can deliver more power for a given motor size compared to BLDC motors.

In terms of control, BLDC motors are usually controlled using a six-step commutation strategy, while PMSM motors require more complex and sophisticated control algorithms. PMSM motors typically require position and speed feedback for precise control. This adds complexity and cost to the motor control system but allows for better speed and torque control, ideal for applications that require high performance and accuracy.

Anhui Mingteng Permanent Magnet Electrical&machinery Equipment Co., Ltd. is a modern high-tech enterprise that integrates the research and development, manufacturing, sales, and service of permanent magnet motors. We have a professional research and development team of over 40 permanent magnet motors, fully understanding the technical requirements of various driving equipment in various industries. The company’s permanent magnet synchronous motors have successfully operated on multiple loads such as fans, water pumps, belt conveyors, ball mills, mixers, crushers, scraper machines, and oil extraction machines in different fields such as cement, mining, steel, and electricity, achieving good energy-saving effects and receiving widespread praise. We are looking forward to more and more Minteng PM motors being applied to various working conditions to save energy and reduce consumption for enterprises!

Post time: Nov-02-2023